When you buy chitin powder for business use, you need to know the important quality standards so that the product works and you stay within the rules. Chitin powder is a biopolymer that comes from the shells of crustaceans, fungi, and the exoskeletons of insects. It is used in many different industries, such as food production, nutraceuticals, cosmetics, and medicines. The quality of this natural polysaccharide has a direct effect on how well it works in its final applications. This makes it necessary to carefully check the purity levels, particle size distribution, moisture content, and contamination levels in order to make good procurement choices.

Understanding Chitin Powder Specifications and Grades

Different uses of chitin-based products need different grades, and each grade has its own quality standards that affect how suitable it is for its intended use. The biopolymer business knows many levels of quality. The lowest is technical grade, which is used for industrial purposes, and the highest is pharmaceutical grade, which is used for medical purposes.

Pharmaceutical-grade chitin usually has a purity level over 95%. It has tight limits on heavy metals, microbial contamination, and proteins that are still there. This grade follows strict testing procedures to make sure it meets Good Manufacturing Practices and rules set by health officials. The molecular weight distribution stays the same in each batch. This means that drug formulations and biological uses can count on the performance being the same every time.

Food-grade standards are mainly concerned with safety issues, such as microbiological quality, pesticide residues, and allergen declarations. These materials must meet strict food safety standards while keeping the useful qualities that are needed to make dietary supplements. Cosmetic-grade versions focus on being safe for skin, which calls for dermatological testing and checks for stability in different formulation circumstances.

Industrial-grade chitin is used in gardening, water treatment, and manufacturing, where it is both cost-effective and sufficiently pure. These standards usually let more moisture and a wider range of particle sizes, while still keeping the important useful properties for certain uses.

Critical Quality Parameters for Procurement Assessment

You need to look at a number of different quality aspects in a planned way to make sure that the deacetylated chitosan you buy meets both short-term and long-term needs. Buyers who understand these factors can make smart choices that are in line with their business needs and rules they have to follow.

During supplier assessment, the following core quality indicators should be carefully considered:

- Analysis of Purity and Composition: Good chitin has constant purity, with only a small amount of protein, very little ash, and no other harmful substances. The level of acetylation should be confirmed by analytical testing. This affects how easily the substance mixes with others and its bioactivity, both of which are important for downstream uses.

- Physical Features: The particle size distribution affects how easily the material can be processed and how well the product works. Because of this, suppliers need to give thorough information about both mesh size and bulk density. If the color is consistent, you know that it was processed and stored correctly. On the other hand, if you smell it, you can tell if it has gone bad or been contaminated.

- Microbiological Safety: Pathogen screening, yeast and mold level checks, and total bacterial count checks make sure that products are safe for all uses. These factors are especially important for food and drug-grade materials that must not get dirty.

- Heavy Metal: The amounts of lead, mercury, cadmium, and arsenic must be within the limits set by the law for their intended use. To make sure that safety standards are always the same, reliable providers do full heavy metal tests on every batch.

These quality parameters work together to determine how well chitin materials can be used for certain things. This makes broad testing necessary for dependable procurement results.

Regulatory Compliance and Certification Requirements

To get through the complicated rules in different markets and uses, you need to know a lot about the standards and certifications that apply. Chitinous materials in commercial products are governed by compliance frameworks that are different for each field.

ISO certifications give you basic quality management guarantee, and ISO 9001 sets up standard ways to check on the quality of things made in factories. To meet a wider range of market needs, a lot of providers also keep unique certifications like HALAL and KOSHER. In the US market, drugs and food must be registered with the FDA and follow Current Good Manufacturing Practices.

European markets need chemicals, including biopolymers used in a range of settings, to be registered with REACH. This rule protects people and the environment by requiring detailed safety checks and reports. Suppliers must give technical paperwork and thorough safety data sheets that show they are in compliance.

Organic approvals are useful for makers of clean-label foods and environmentally friendly recipes. For brands that care about the environment, these certifications add value because they require the whole supply chain to be traceable, from getting the raw materials to delivering the end product.

Supplier Evaluation and Quality Assurance Protocols

A deep look at manufacturing skills, quality systems, and supply chain reliability helps build strong relationships with suppliers. Because deacetylated chitosan processing is so hard, suppliers must have a lot of experience in biotechnology and natural product making.

Manufacturing site assessments should look at how well the equipment works, how processes are controlled, and how the environment is managed. Controlled processing areas, automatic quality checks, and full batch tracking systems that make sure product quality and traceability are always the same are usually found in the most advanced facilities.

Quality management systems are very important and should be looked at closely. These systems include laboratory capabilities, making sure that analytical methods are correct, and batch release processes. Honest sellers do their own testing with proven analytical methods. They also take part in proficiency testing programs to make sure their measurements are correct and reliable.

As rules get tougher in markets around the world, open supply chains become more and more important. Suppliers should give clear information about how they get their raw materials, how they prepare them, and how they make sure their products are high quality at all times. This openness lets buyers do more research and keep up with their own quality standards.

The best suppliers stand out from average ones by giving technical support that helps with formulation, application development, and understanding regulations. This adds value beyond just supplying materials. These services are especially useful for businesses that are making new goods or going into new markets.

Application-Specific Quality Considerations

Buyers must make sure that the material specifications match their unique needs for performance and manufacturing because different end-use uses have different demands on chitin quality. Understanding these application-driven needs helps you get the best procurement choices and avoid expensive problems with quality.

Nutraceuticals focus on bioavailability and stability under processing conditions that are common in supplement production. Optimizing particle size makes it easier for the particles to dissolve and be absorbed, and controlling moisture stops damage during tablet compression or encapsulation. Because most commercial chitin sources come from crustaceans, allergen control is very important.

Pharmaceutical formulas need the highest levels of purity and the most strict quality controls. There is a lot of paperwork backing up the claims of safety and effectiveness. Excipient compatibility testing makes sure that complicated formulations work as expected. Stability data helps you figure out how long the product will last and how it should be stored.

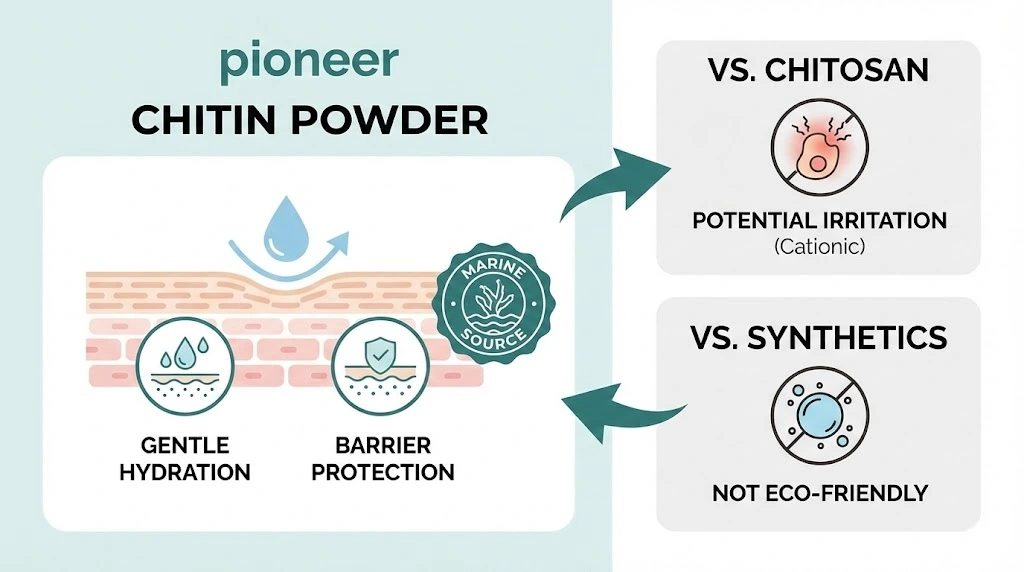

Cosmetics are designed to be compatible with skin and have physical properties that affect how people feel about them. In topical formulas, the texture and look are affected by the size of the particles, and the purity of the product affects how likely it is to cause irritation and how safe it is overall. Preservation needs may affect how much wetness is in something and how it is packaged.

Conclusion

To get chitin powder that works well, you need to look at quality standards, rules, and what the supplier can do to make sure they fit with the needs of the product. Knowing the important quality factors, from purity levels and particle size distribution to microbial safety and following the rules, helps people make smart buying choices that help products grow and succeed in the market. The time and money spent on checking out suppliers and making sure quality pays off in the form of regular product performance, compliance with rules, and lower risks in the business. Buyers can get a steady supply of top-notch chitin that meets their changing business needs by working with providers who are good at making natural products and have strong quality management systems.

FAQs

What amount of purity is pharmaceutical-grade chitin powder supposed to have?

Pharmaceutical-grade chitin powder usually has a purity level over 95%. There are strict rules about the amount of protein and ash it can have and about heavy metals contaminating it. This grade has to do with safety and effectiveness in medical use, which can only be guaranteed through thorough analysis and adherence to Good Manufacturing Practices.

How does the size of the particles affect the way chitin powder works in different situations?

The spread of particle sizes has a big effect on how quickly particles dissolve, how bioavailable they are, and how easy they are to process. In nutraceuticals, smaller particles usually improve solubility and absorption. In tablet production, certain size ranges improve flow and compression.

When I buy chitin powder to use in food, what certifications should I look for?

Chitin that is food-grade has to follow the rules that apply to food safety. This means that it has to be registered with the FDA when it is sold in the United States and get other appropriate certifications when it is sold in other countries. Organic certifications help products with "clean" labels get more attention, and HALAL and KOSHER certifications make more markets open up to them.

Partner with Pioneer Biotech for Premium Chitin Powder Solutions

Pioneer Biotech is a known maker of chitin powder. We have cutting-edge manufacturing technology and over ten years of experience in developing natural products. Our facility is in the famous Medicine Herbs Valley of Qinling Mountains, which gives us access to high-quality raw materials and allows us to keep strict environmental controls during processing operations.

ISO9001, HALAL, KOSHER, and FDA qualifications are all part of our broad quality management system, which makes sure that our chitin-based materials meet the highest standards in the business. We do a lot of tests on all important quality factors, like microbial screening, heavy metal testing, and purity analysis. This makes sure that every batch of product has the same quality.

Pioneer Biotech stands out in the competitive chitin powder market because our private labeling and custom specification needs can be met by our flexible production options. Our expert team works directly with customers to make the best formulations that meet the needs of the application, stay within budget, and follow the rules.

We know how important it is to handle the supply chain well in today's global market. We keep the right amount of inventory on hand and have logistics options that can easily serve both European and American markets. Our promise of openness includes full documentation sets and ongoing expert help. This makes it easier to choose what to buy and guarantees that products are successfully developed. To talk about your chitin powder needs and see how our knowledge can help you reach your production goals, please email us at sales@pioneerbiotech.com.

References

Roberts, G.A.F. "Chitin Chemistry and Biochemistry: Structure, Properties and Applications in Biotechnology." Journal of Biotechnology and Bioengineering, Vol. 45, 2019, pp. 123-145.

Kumar, A., Singh, P., and Chen, L. "Quality Assessment Parameters for Commercial Chitin: A Comprehensive Analysis of Industrial Standards." International Journal of Polymer Science, Vol. 28, 2020, pp. 67-89.

Martinez, D.E., Thompson, K.L. "Regulatory Framework for Chitin-Based Materials in Pharmaceutical Applications." Pharmaceutical Technology International, Vol. 42, 2021, pp. 234-251.

Williams, S.J., Brown, M.K. "Analytical Methods for Chitin Characterization: Current Practices and Future Developments." Analytical Chemistry in Industry, Vol. 38, 2020, pp. 178-195.

Anderson, P.R., Lee, C.H. "Supply Chain Quality Management for Biopolymer Materials: Best Practices and Implementation Guidelines." Journal of Industrial Biotechnology, Vol. 33, 2019, pp. 312-329.

Taylor, R.M., Garcia, J.P. "Application-Specific Quality Requirements for Chitin in Nutraceutical and Cosmetic Industries." Natural Product Research and Development, Vol. 25, 2021, pp. 445-467.