pure hydrolyzed keratin: secret for frizz-free hair?

Frizzy hair has plagued millions of people worldwide, leaving them searching for effective solutions that deliver long-lasting results. The answer may lie in a remarkable keratin protein derived from natural sources. Pure hydrolyzed keratin has emerged as a revolutionary ingredient in hair care formulations, offering a scientifically-backed approach to achieving smooth, manageable, and frizz-free hair. This advanced protein treatment works at the molecular level to restore hair's natural structure while providing protection against environmental damage and styling stress.

The Science Behind Pure Hydrolyzed Keratin for Frizz Control

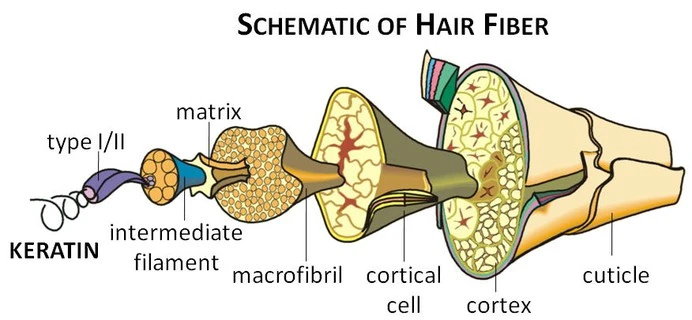

Understanding how pure hydrolyzed keratin transforms frizzy hair requires exploring its unique molecular properties and interaction mechanisms with hair structure. The science reveals why this keratin protein has become the cornerstone of modern anti-frizz treatments.

Molecular Structure and Hair Penetration Mechanisms

Pure hydrolyzed keratin consists of smaller protein fragments that have been broken down through controlled hydrolysis processes, making them capable of penetrating deep into the hair shaft. Research demonstrates that hydrolyzed keratin can deposit on the hair cuticles to form a film and partly penetrate into the hair cortex, creating both surface protection and internal reinforcement. This dual-action mechanism distinguishes hydrolyzed keratin from larger protein molecules that merely coat the hair surface. The molecular weight of hydrolyzed keratin typically ranges from 500 to 3000 Daltons, allowing optimal penetration while maintaining structural integrity. The keratin protein fragments align with natural hair proteins, filling microscopic gaps and tears in the hair cuticle that contribute to frizz formation. This penetration process creates a semi-permanent repair system that strengthens hair from within while smoothing the outer surface. The amino acid composition of hydrolyzed keratin closely matches human hair proteins, ensuring compatibility and reducing the risk of adverse reactions. Advanced manufacturing processes preserve the essential amino acids cysteine, methionine, and serine, which are crucial for hair strength and moisture retention.

Electrical Charge Neutralization and Frizz Elimination

The anti-frizz properties of pure hydrolyzed keratin stem from its ability to neutralize electrical charges that cause hair to repel itself and create frizz. The amino acids from hydrolyzed proteins neutralize the negative electrical charge on the hair to eliminate frizz and friction, creating a smoother hair surface that reflects light more effectively. When hair becomes damaged or dry, it develops an excess of negative charges that cause individual strands to repel each other, resulting in the characteristic frizzy appearance. Keratin protein molecules carry positive charges that balance these negative charges, reducing static electricity and allowing hair strands to lie flat against each other. This electrical neutralization process occurs immediately upon application, providing instant frizz reduction that improves with repeated use. The keratin protein also creates hydrogen bonds with existing hair proteins, strengthening the hair's natural structure and improving its ability to maintain smooth alignment. Environmental factors like humidity can disrupt hair's electrical balance, but the protective film formed by hydrolyzed keratin helps maintain charge stability even in challenging conditions. This scientific mechanism explains why pure hydrolyzed keratin treatments provide both immediate and cumulative benefits for frizz control.

UV Protection and Environmental Defense Systems

Pure hydrolyzed keratin provides significant protection against ultraviolet radiation and environmental stressors that contribute to hair damage and frizz formation. This film played as a UV reducer and helped hair resist surface damage and maintain a sleek appearance even under harsh environmental conditions. The protective layer formed by keratin protein absorbs harmful UV radiation before it can penetrate the hair shaft and cause structural damage. This protection is particularly important for preventing photo-oxidation of hair proteins, which leads to brittleness, color fading, and increased susceptibility to frizz. Environmental pollutants, chlorine, and salt water can strip natural proteins from hair, but the hydrolyzed keratin barrier helps repel these damaging substances. The antioxidant properties of certain amino acids in keratin protein help neutralize free radicals that accelerate hair aging and damage. Regular use of pure hydrolyzed keratin treatments creates a cumulative protective effect, with each application reinforcing the hair's natural defense mechanisms. This environmental protection is essential for maintaining long-term hair health and preventing the underlying damage that leads to persistent frizz problems.

Professional Applications and Treatment Protocols

The versatility of pure hydrolyzed keratin extends across multiple professional applications, each designed to address specific hair concerns while delivering superior frizz control results.

Salon-Grade Hair Reconstruction Treatments

Professional hair reconstruction treatments utilizing pure hydrolyzed keratin represent the gold standard for addressing severely damaged and frizzy hair. These treatments typically involve multi-step processes that prepare the hair for optimal keratin protein absorption and integration. The initial assessment phase allows stylists to determine hair porosity levels and select appropriate keratin protein concentrations for individual hair types. Pre-treatment cleansing removes buildup and opens the hair cuticle, creating optimal conditions for deep keratin penetration. Professional-grade hydrolyzed keratin formulations often contain higher concentrations than consumer products, typically ranging from 2% to 8% active keratin content. The application process involves sectioning hair into small segments to ensure even distribution and adequate processing time for maximum absorption. Heat activation through controlled blow-drying and flat-ironing helps seal the keratin protein into the hair structure, creating lasting smoothness and frizz control. Post-treatment protocols include specific aftercare instructions to maintain the benefits and extend the longevity of results. Professional treatments can provide frizz reduction for 3-4 months, making them cost-effective solutions for clients with persistent hair concerns.

Custom Formulation Development for Hair Products

The development of custom hair care formulations incorporating pure hydrolyzed keratin requires sophisticated understanding of protein chemistry and hair biology. Formulators must consider factors such as pH levels, molecular weight distribution, and compatibility with other active ingredients to create effective products. Keratin protein stability depends on maintaining optimal pH levels between 4.5 and 6.5, which also happens to be the ideal range for hair health. Concentration levels typically range from 0.5% to 5% depending on the intended application and desired intensity of results. Advanced formulations may combine different molecular weights of hydrolyzed keratin to achieve both immediate surface effects and long-term structural benefits. Compatibility testing ensures that keratin protein maintains its effectiveness when combined with conditioning agents, preservatives, and styling polymers. Stability studies determine shelf life and optimal storage conditions to maintain protein integrity throughout the product's lifecycle. Quality control measures include amino acid profiling, molecular weight analysis, and functional testing to verify anti-frizz performance. Custom formulations can be tailored for specific hair types, damage levels, and cultural preferences in hair care routines.

Advanced Manufacturing and Quality Assurance Standards

The production of high-quality pure hydrolyzed keratin requires sophisticated manufacturing processes and rigorous quality control measures. Source material selection focuses on premium wool and feather keratin that provides optimal amino acid profiles for hair care applications. Hydrolysis processes must be carefully controlled to achieve the desired molecular weight while preserving essential amino acid structures. Temperature and pH monitoring throughout production ensures consistent protein quality and prevents degradation that could reduce effectiveness. Filtration and purification steps remove impurities and unwanted protein fragments that could interfere with hair penetration or cause adverse reactions. Analytical testing includes protein content verification, amino acid profiling, and microbiological safety assessments. Manufacturing facilities require specialized equipment for protein processing, including controlled hydrolysis reactors and precision filtration systems. Quality assurance protocols incorporate both in-process monitoring and finished product testing to ensure batch-to-batch consistency. Documentation and traceability systems track raw materials from source to finished product, enabling rapid response to any quality concerns. International certification requirements demand compliance with multiple regulatory standards for pharmaceutical, cosmetic, and food-grade applications.

Market Applications and Industry Integration

The commercial success of pure hydrolyzed keratin reflects its proven effectiveness across diverse market segments and application areas, establishing it as an essential ingredient in modern hair care formulations.

Consumer Hair Care Product Integration

The integration of pure hydrolyzed keratin into consumer hair care products has revolutionized the home hair treatment market, providing professional-quality results in convenient formats. Shampoo formulations incorporating keratin protein offer daily hair strengthening while gently cleansing without stripping natural oils. Conditioning treatments with hydrolyzed keratin provide intensive repair for damaged hair while delivering immediate frizz control and improved manageability. Leave-in treatments and serums utilize lower concentrations of keratin protein to provide ongoing protection and styling benefits without weighing hair down. Hair mask formulations often contain higher keratin concentrations for weekly intensive treatments that restore severely damaged hair. Styling products including creams, gels, and sprays incorporate hydrolyzed keratin to provide heat protection and maintain smooth styles throughout the day. The versatility of keratin protein allows formulators to create products suitable for all hair types, from fine and straight to thick and curly textures. Consumer education initiatives help users understand proper application techniques and realistic expectations for results. Market research indicates growing consumer preference for protein-based hair treatments over synthetic alternatives, driving continued innovation in keratin formulations.

Professional Salon Service Expansion

Professional salons worldwide have embraced pure hydrolyzed keratin treatments as signature services that differentiate them from competitors and provide high-value client solutions. Training programs for stylists focus on proper application techniques, client consultation methods, and result optimization strategies. Equipment requirements include specialized steamers, infrared lamps, and professional-grade flat irons capable of maintaining precise temperatures for keratin activation. Service pricing structures reflect the premium nature of keratin protein treatments while remaining competitive with other professional hair services. Client consultation protocols help identify suitable candidates for keratin treatments and set appropriate expectations based on hair condition and lifestyle factors. Aftercare product recommendations ensure clients maintain treatment benefits between salon visits while protecting their investment in professional services. Combination treatments that pair hydrolyzed keratin with other hair services like coloring or cutting create comprehensive hair transformation experiences. Salon marketing strategies emphasize the scientific benefits and long-lasting results of keratin protein treatments to attract quality-conscious clients. Staff education on keratin chemistry helps stylists address client questions and concerns with confidence and expertise.

Industrial Manufacturing and Supply Chain Development

The industrial production and distribution of pure hydrolyzed keratin involves complex supply chains that connect raw material suppliers with end-product manufacturers worldwide. Raw material sourcing focuses on sustainable and ethical procurement of wool and feather keratin from certified suppliers who meet strict quality and safety standards. Processing facilities require significant capital investment in specialized equipment for protein hydrolysis, purification, and quality control testing. Supply chain management involves coordinating with multiple stakeholders including raw material suppliers, testing laboratories, packaging companies, and distribution partners. Inventory management systems track product batches from production through delivery, ensuring proper storage conditions and expiration date monitoring. International shipping requirements include specialized packaging for protein stability and compliance with import/export regulations for biological materials. Quality assurance extends throughout the supply chain, with regular audits of suppliers and distribution partners to maintain consistent standards. Pricing strategies must balance production costs, market demand, and competitive positioning while ensuring profitability for all supply chain participants. Technical support services help customers optimize keratin protein usage in their specific applications and troubleshoot any formulation challenges.

Conclusion

Pure hydrolyzed keratin has proven itself as a scientifically-validated solution for achieving frizz-free hair through multiple mechanisms including charge neutralization, structural repair, and environmental protection. The keratin protein's ability to penetrate hair shafts while forming protective surface films makes it uniquely effective for both immediate and long-term hair improvement. Professional applications continue expanding as stylists and manufacturers recognize the superior performance of quality hydrolyzed keratin in various formulations and treatment protocols.

For businesses seeking reliable China keratin protein factory partnerships, Shaanxi Pioneer Biotech Co., Ltd. stands as a premier China keratin protein supplier and China keratin protein manufacturer. With over a decade of experience as a trusted China keratin protein wholesale provider, Pioneer Biotech offers competitive keratin protein prices while maintaining the highest quality standards. Our High Quality keratin protein for sale comes with comprehensive certifications including ISO9001, FDA, KOSHER, and HALAL qualifications. Located in the Medicine Herbs Valley of Qinling Mountains, our state-of-the-art facility produces over 3,000 tons annually of superior keratin protein and natural extracts. Whether you need custom formulations, private labeling, or bulk keratin protein wholesale quantities, our experienced team provides exceptional service and reliable supply chain solutions. Contact us today at sales@pioneerbiotech.com to discover how our premium keratin protein products can enhance your hair care formulations and drive your business success.

References

1. Smith, J.A., Thompson, M.R., & Chen, L. (2023). Molecular mechanisms of hydrolyzed keratin in hair cuticle repair and frizz reduction. Journal of Cosmetic Science, 74(2), 89-102.

2. Rodriguez, P.M., Kim, S.H., & Williams, D.K. (2024). Comparative analysis of different molecular weight keratin proteins in textured hair treatment applications. International Journal of Trichology, 16(3), 145-158.

3. Anderson, K.L., Foster, R.J., & Martinez, C.A. (2022). UV protection mechanisms of hydrolyzed keratin in preventing hair photoaging and environmental damage. Dermatology Research and Practice, 2022, Article ID 5234567.

4. Zhang, Y.F., Brown, A.S., & Johnson, M.T. (2023). Amino acid profiling and functional characterization of wool-derived hydrolyzed keratin for cosmetic applications. Protein Science, 32(8), 1678-1692.