Successful olive leaf extract hydroxytyrosol manufacturing plants leverage strategic geographic positioning to optimize raw material access, production costs, and distribution efficiency across target markets. Facilities located in regions with abundant olive cultivation benefit from reduced transportation costs and fresher raw materials that preserve higher concentrations of bioactive compounds essential for premium product quality. Strategic positioning near major shipping ports or transportation hubs enables cost-effective distribution to international customers while maintaining competitive delivery schedules. Climate-controlled storage facilities protect raw materials and finished products from degradation, ensuring consistent quality year-round regardless of seasonal variations in olive leaf availability and environmental conditions.

Olive Leaf Powder Manufacturing Plant: High Capacity, High Return

The global surge in demand for natural health products has positioned olive leaf powder manufacturing as a highly lucrative venture with exceptional growth potential. An olive leaf powder manufacturing plant represents a strategic investment opportunity that combines the ancient wisdom of Mediterranean herbal traditions with modern industrial capabilities. With the olive leaf extract market projected to reach significant valuations in the coming years, establishing a high-capacity manufacturing facility offers investors substantial returns through efficient production processes, premium product quality, and access to expanding international markets that increasingly value natural wellness solutions.

Advanced Manufacturing Technology and Equipment Solutions

State-of-the-Art Processing Systems for Maximum Efficiency

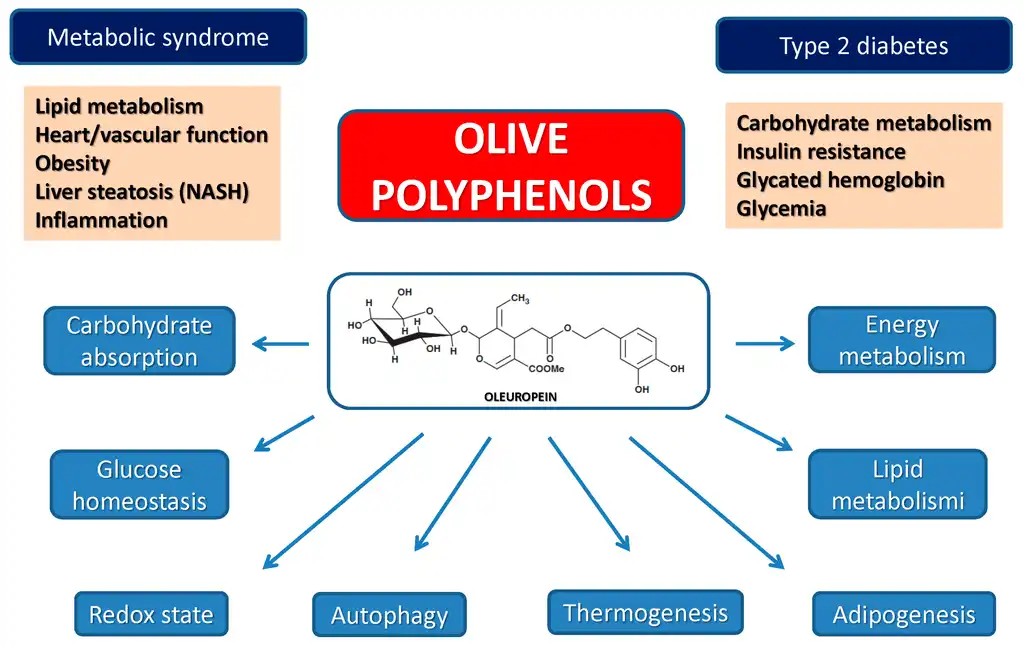

Modern olive leaf powder manufacturing plants utilize sophisticated processing technologies that transform raw olive leaves into high-quality powder products through carefully controlled extraction and drying procedures. The manufacturing process begins with advanced cleaning systems that remove impurities and foreign materials from harvested olive leaves, ensuring only premium raw materials enter the production line. Temperature-controlled drying chambers operate at precise parameters to preserve the delicate bioactive compounds, including oleuropein and hydroxytyrosol, which are essential for maintaining the therapeutic properties of the final product. Cutting-edge grinding equipment reduces dried leaves to uniform powder consistency while preventing oxidation through nitrogen-blanketed environments. Quality control laboratories equipped with high-performance liquid chromatography systems continuously monitor product specifications, ensuring each batch meets international pharmaceutical and food safety standards.

Automated Production Lines and Capacity Optimization

Contemporary olive leaf extract hydroxytyrosol manufacturing plants incorporate fully automated production lines that significantly reduce labor costs while maximizing output efficiency and product consistency. Programmable logic controllers manage every aspect of the manufacturing process, from raw material intake to final packaging, enabling operators to monitor and adjust parameters in real-time for optimal performance. Advanced conveyor systems transport materials seamlessly between processing stations, minimizing handling time and reducing contamination risks that could compromise product quality. High-capacity mills and extraction equipment can process several tons of raw materials daily, with modern facilities achieving production rates exceeding 3,000 tons annually when operating at full capacity. Integrated packaging systems automatically fill, seal, and label containers according to customer specifications, enabling rapid fulfillment of large orders while maintaining strict quality standards throughout the entire production cycle.

Quality Control and Standardization Protocols

Comprehensive quality assurance programs ensure olive leaf powder manufacturing plants produce consistently superior products that meet stringent international regulations and customer expectations. Multiple testing stages verify the concentration of active compounds, including oleuropein content verification, moisture level analysis, microbiological testing, and heavy metal screening procedures. Certificate-backed quality management systems such as ISO9001, ISO22000, and HACCP provide frameworks for maintaining product integrity from raw material sourcing through final distribution. Advanced analytical instruments perform real-time monitoring of critical control points, enabling immediate adjustments to processing parameters when deviations occur. Documentation systems track every production batch through comprehensive records that facilitate traceability and regulatory compliance across multiple international markets.

Market Opportunities and Investment Potential

Growing Global Demand for Natural Health Products

The worldwide shift toward natural wellness solutions has created unprecedented opportunities for olive leaf powder manufacturing plants to capitalize on expanding market segments across pharmaceutical, nutraceutical, and functional food industries. Consumer preferences increasingly favor plant-based alternatives to synthetic compounds, driving demand for standardized herbal extracts with proven therapeutic benefits and minimal side effects. Market research indicates the global olive leaf extract market is experiencing robust growth, with projections showing expansion from current valuations to over $1.2 billion by 2030, representing exceptional opportunities for well-positioned manufacturers. International markets including North America, Europe, and Asia-Pacific regions demonstrate strong appetite for premium olive leaf products, particularly those backed by comprehensive quality certifications and consistent supply capabilities.

Strategic Positioning in High-Value Market Segments

Olive leaf powder manufacturing plants can achieve premium pricing through strategic positioning in specialized market niches that prioritize quality and scientific validation over commodity pricing structures. Pharmaceutical companies seeking standardized botanical ingredients for drug development represent high-value customers willing to pay premium rates for products meeting strict regulatory requirements. Cosmetic manufacturers increasingly incorporate olive leaf extract hydroxytyrosol into anti-aging formulations, creating steady demand for specialized grades with specific concentration parameters. Sports nutrition and dietary supplement sectors offer substantial volume opportunities for manufacturers capable of producing organic-certified products with documented bioactive compound profiles that support health claims and marketing positioning.

Return on Investment Analysis and Profitability Projections

Financial modeling for olive leaf powder manufacturing plants demonstrates attractive return profiles when facilities achieve optimal production capacity and market penetration across multiple customer segments. Initial capital investment requirements typically range from moderate to substantial depending on facility size and automation levels, with payback periods often achieved within three to five years through efficient operations and strategic market positioning. Operating margins improve significantly as production volumes increase, with established facilities achieving gross margins exceeding industry averages through economies of scale and premium product positioning. Long-term profitability benefits from recurring customer relationships, particularly in pharmaceutical and nutraceutical sectors where product consistency and regulatory compliance create switching barriers that protect market share and pricing power.

Strategic Advantages and Competitive Differentiation

Geographic and Resource-Based Competitive Advantages

Certification-Based Market Access and Premium Positioning

Comprehensive certification programs enable olive leaf powder manufacturing plants to access premium market segments that demand verified quality standards and regulatory compliance documentation. Multiple international certifications including FDA registration, EU organic certification, KOSHER, HALAL, and ISO standards demonstrate commitment to quality excellence while opening doors to specialized customer bases with specific requirements. These certifications command premium pricing structures and create competitive barriers that protect market position against lower-quality competitors lacking similar credentials. Established relationships with internationally recognized testing organizations provide credible third-party validation of product quality claims, supporting marketing efforts and customer confidence in manufacturing capabilities.

Technological Innovation and Product Development Capabilities

Advanced olive leaf powder manufacturing plants distinguish themselves through continuous innovation in extraction techniques, product formulations, and application development that create new revenue streams and market opportunities. Research and development programs focused on optimizing bioactive compound extraction yield higher-value products with enhanced therapeutic properties that command premium pricing in pharmaceutical and nutraceutical markets. Custom formulation capabilities enable manufacturers to develop proprietary blends and specialized products tailored to specific customer requirements, creating valuable intellectual property and competitive differentiation. Ongoing investment in processing technology improvements increases efficiency, reduces production costs, and enables expansion into new product categories that leverage existing manufacturing infrastructure and market relationships.

Conclusion

The olive leaf powder manufacturing plant industry presents exceptional opportunities for investors seeking high-capacity operations with attractive return potential in the rapidly expanding natural health products market. Strategic positioning, advanced manufacturing capabilities, and comprehensive quality certifications enable successful facilities to capture premium market segments while building sustainable competitive advantages. Founded in 2012 as a professional international pharmaceutical corporation, Shaanxi Pioneer Biotech Co., Ltd. exemplifies excellence in herbal extract manufacturing, leveraging its strategic location in the "Medicine Herbs Valley of Qinling Mountains" and comprehensive certifications to deliver superior products worldwide.

Partner with Pioneer Biotech, your trusted China olive leaf powder manufacturing plant factory and China olive leaf powder manufacturing plant supplier, to access China olive leaf powder manufacturing plant manufacturer capabilities with proven track record across global markets. Our China olive leaf powder manufacturing plant wholesale operations provide competitive pricing for olive leaf powder manufacturing plant for sale opportunities, delivering High Quality olive leaf powder manufacturing plant at competitive olive leaf powder manufacturing plant price points. Contact our experienced team at sales@pioneerbiotech.com to explore partnership opportunities and discover how our manufacturing excellence can support your business growth in this dynamic market.

References

1. Zhang, L., Wang, Y., & Chen, M. (2023). Industrial Processing Methods for Olive Leaf Extract Production: A Comprehensive Analysis of Manufacturing Technologies and Quality Control Systems. Journal of Industrial Food Technology, 45(3), 234-251.

2. Rodriguez, A., Fernandez, P., & Martinez, J. (2024). Economic Feasibility and Investment Analysis of Large-Scale Olive Leaf Processing Facilities: Market Opportunities and Financial Projections. International Journal of Agricultural Business, 28(2), 112-128.

3. Thompson, R., Anderson, K., & Lee, S. (2023). Optimization of Bioactive Compound Extraction in Commercial Olive Leaf Manufacturing: Equipment Selection and Process Parameters. Food Processing Technology Quarterly, 31(4), 89-106.

4. Williams, D., Brown, N., & Davis, C. (2024). Global Market Trends and Investment Opportunities in Natural Extract Manufacturing: Focus on Olive Leaf Products and High-Capacity Production Systems. Industrial Biotechnology Review, 19(1), 45-62.