Alpha GPC Powder Factory With Customized Bulk Packaging Options

In today's rapidly evolving nutraceutical landscape, finding a reliable alpha gpc powder factory that offers comprehensive customized bulk packaging solutions has become increasingly crucial for businesses seeking to establish their presence in the cognitive enhancement market. The growing demand for L-alpha glycerylphosphorylcholine, commonly known as choline alfoscerate, has driven manufacturers to develop sophisticated production facilities that not only ensure premium quality but also provide flexible packaging options tailored to diverse client requirements. As the cognitive supplement industry continues to expand globally, partnering with an established alpha gpc powder factory becomes essential for companies looking to deliver high-quality products while maintaining competitive advantages in their respective markets.

Manufacturing Excellence and Quality Assurance Standards

Advanced Production Capabilities and Infrastructure

Modern alpha gpc powder factory operations require sophisticated infrastructure to ensure consistent quality and scalability. Leading facilities strategically position themselves in regions rich in natural resources, such as the Medicine Herbs Valley of Qinling Mountains, where environmental conditions naturally support the production of high-quality herbal extracts. These facilities typically span thousands of square meters and incorporate state-of-the-art extraction technologies that can process over 3,000 tons of various herbal extracts annually. The manufacturing process for choline alfoscerate involves precise temperature control, optimal pH management, and stringent purification protocols to achieve the desired 99% purity levels. Contemporary alpha gpc powder factory operations utilize advanced chromatographic techniques, including high-performance liquid chromatography (HPLC), to ensure molecular integrity throughout the production cycle. The implementation of automated systems minimizes human error while maximizing efficiency, allowing manufacturers to meet growing global demand for alpha gpc powder while maintaining consistent quality standards across all production batches.

Comprehensive Certification and Regulatory Compliance

Establishing credibility in the international market requires alpha gpc powder factory operations to obtain multiple certifications that demonstrate adherence to global quality standards. Essential certifications include ISO9001 for quality management systems, ISO22000 for food safety management, and HACCP for hazard analysis and critical control points. Religious certifications such as KOSHER and HALAL ensure the product meets dietary requirements for diverse consumer bases worldwide. Organic certifications from both EU and USDA regulatory bodies validate the natural sourcing and processing methods used in choline alfoscerate production. FDA registration provides additional assurance for North American markets, while SGS certification offers third-party verification of quality standards. These comprehensive certifications not only build consumer trust but also facilitate easier market entry across different geographical regions. The rigorous testing protocols associated with these certifications ensure that every batch of alpha gpc powder meets international safety and efficacy standards, providing businesses with confidence in their supply chain integrity.

Quality Control and Testing Protocols

Sophisticated quality control measures form the backbone of any reputable alpha gpc powder factory, ensuring that choline alfoscerate products consistently meet pharmaceutical-grade standards. Multi-stage testing begins with raw material verification, where incoming herbal materials undergo comprehensive analysis for purity, potency, and contamination screening. During production, real-time monitoring systems track critical parameters such as temperature, pressure, and pH levels to maintain optimal extraction conditions. Post-production testing involves detailed analytical procedures including HPLC analysis for molecular composition verification, microbiological testing for pathogen detection, and heavy metal screening to ensure safety compliance. Certificate of Analysis (COA) documentation accompanies each batch, providing detailed information about purity levels, residual solvents, and bioactive compound concentrations. Advanced alpha gpc powder factory facilities also implement environmental monitoring systems to ensure production areas maintain appropriate humidity and temperature levels that preserve product stability. These comprehensive quality assurance protocols guarantee that customers receive consistently high-quality alpha gpc powder that meets or exceeds industry specifications for pharmaceutical, nutraceutical, and cosmetic applications.

Customized Bulk Packaging Solutions and Services

Flexible Packaging Options for Diverse Market Needs

Understanding that different markets require specific packaging configurations, leading alpha gpc powder factory operations offer extensive customization options to meet varied client requirements. Standard packaging typically includes aluminum foil bags ranging from 1kg to 25kg capacity, with fiber drums available for larger quantities to ensure product stability during storage and transportation. Custom packaging solutions extend beyond basic containers to include specialized moisture-barrier packaging for tropical climates, vacuum-sealed options for extended shelf life, and tamper-evident features for enhanced security. The alpha gpc powder packaging can be tailored to specific market regulations, incorporating multilingual labeling, region-specific regulatory information, and custom branding elements that align with client marketing strategies. Advanced packaging technologies such as nitrogen flushing help preserve choline alfoscerate potency by preventing oxidation during storage. For pharmaceutical applications, packaging must meet stringent regulatory requirements including child-resistant features and detailed batch tracking information. Cosmetic industry clients often require smaller, consumer-friendly packaging with aesthetic appeal and easy dispensing mechanisms. The flexibility in packaging options allows businesses to optimize their inventory management while ensuring product integrity across diverse distribution channels.

Private Labeling and Brand Development Support

Comprehensive private labeling services transform alpha gpc powder factory relationships from simple supply arrangements into strategic partnerships that support brand development and market expansion. These services typically include custom label design, logo integration, and product information formatting that complies with regional regulatory requirements. Professional alpha gpc powder factory operations provide marketing support through high-quality product photography, technical data sheets, and safety documentation that clients can use in their promotional materials. The private labeling process extends to custom formulation development, where experienced chemists work with clients to create unique blends that incorporate choline alfoscerate with complementary ingredients for enhanced efficacy. Regulatory support services help navigate complex compliance requirements across different markets, ensuring that private label products meet all necessary safety and efficacy standards. Quality assurance documentation for private label products includes batch-specific testing results, stability studies, and shelf-life validation data that support product registration processes. These comprehensive services enable businesses to launch their own branded alpha gpc powder products without investing in manufacturing infrastructure while maintaining complete control over their brand identity and market positioning.

Supply Chain Management and Logistics Excellence

Efficient supply chain management represents a critical competitive advantage for alpha gpc powder factory operations serving global markets. Modern facilities implement sophisticated inventory management systems that track raw material availability, production schedules, and finished product inventory to ensure consistent supply availability. Strategic partnerships with international logistics providers enable reliable delivery to customers worldwide, with specialized handling procedures for temperature-sensitive choline alfoscerate products. Advanced alpha gpc powder factory operations maintain local warehouse facilities in key markets to reduce delivery times and shipping costs for regular customers. Real-time tracking systems provide complete visibility throughout the supply chain, allowing customers to monitor their orders from production through final delivery. Emergency response protocols ensure rapid resolution of supply disruptions, with backup suppliers and expedited shipping options available when needed. The integration of digital platforms enables seamless communication between customers and factory operations, facilitating efficient order processing, documentation exchange, and quality verification. These comprehensive supply chain capabilities ensure that businesses can rely on consistent alpha gpc powder availability to support their production schedules and market commitments while minimizing inventory carrying costs through optimized delivery timing.

Applications and Market Opportunities

Pharmaceutical Industry Integration and Development

The pharmaceutical sector represents one of the most significant growth opportunities for alpha gpc powder factory operations, driven by increasing research into choline alfoscerate's therapeutic potential for neurological conditions. Clinical studies have demonstrated the efficacy of alpha gpc powder in supporting cognitive function, making it an attractive ingredient for pharmaceutical formulations targeting age-related cognitive decline and neurodegenerative disorders. Pharmaceutical companies require consistently high-quality raw materials that meet strict regulatory standards, creating demand for alpha gpc powder factory operations with comprehensive quality assurance systems. The molecular stability of choline alfoscerate under various storage conditions makes it suitable for long-term pharmaceutical applications, while its water solubility facilitates incorporation into diverse dosage forms including tablets, capsules, and liquid formulations. Regulatory approval processes for pharmaceutical applications require extensive documentation of manufacturing processes, quality control procedures, and batch consistency data that established alpha gpc powder factory operations can readily provide. The growing trend toward personalized medicine creates opportunities for customized formulations that combine alpha gpc powder with other cognitive-supporting compounds tailored to specific patient populations. As research continues to unveil new therapeutic applications for choline alfoscerate, pharmaceutical companies increasingly seek reliable factory partnerships that can support both current production needs and future scale-up requirements.

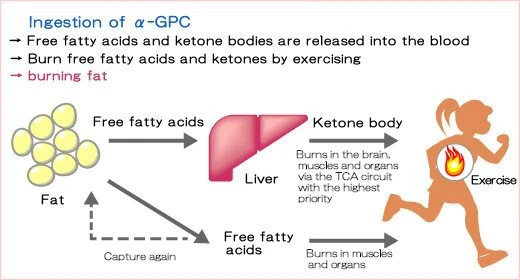

Nutraceutical and Dietary Supplement Market Expansion

The nutraceutical industry represents the largest and fastest-growing market segment for alpha gpc powder factory operations, driven by consumer interest in cognitive enhancement and brain health optimization. Dietary supplement manufacturers increasingly incorporate choline alfoscerate into their formulations due to its superior bioavailability compared to other choline sources and its established safety profile for long-term use. The versatility of alpha gpc powder enables its integration into various supplement formats including standalone cognitive enhancers, comprehensive brain health formulas, and sports nutrition products targeting mental performance. Consumer education about the benefits of choline alfoscerate has increased market demand significantly, creating opportunities for alpha gpc powder factory operations to develop long-term supply relationships with established supplement brands. The trend toward clean-label products drives demand for naturally-sourced alpha gpc powder that meets organic certification standards and contains no synthetic additives or preservatives. International market expansion opportunities exist in regions with growing middle-class populations and increasing health consciousness, particularly in Asia-Pacific and Latin American markets. The ability to provide customized packaging solutions enables supplement manufacturers to optimize their inventory management while ensuring product freshness and potency throughout the distribution chain.

Emerging Applications in Cosmetics and Functional Foods

Innovation in cosmetic applications presents exciting new opportunities for alpha gpc powder factory operations as beauty brands explore the potential of choline alfoscerate for skin health and cognitive wellness cosmetics. The growing trend toward neurocosmetics has created demand for topical formulations that may support mental clarity and stress reduction through transdermal delivery systems. Alpha gpc powder's excellent solubility characteristics make it suitable for incorporation into serums, creams, and specialized beauty products targeting the growing market of consumers seeking multi-functional cosmetic solutions. Functional food applications represent another expanding market segment where choline alfoscerate can enhance the nutritional profile of everyday products including beverages, energy bars, and fortified foods. The clean taste profile of high-quality alpha gpc powder facilitates its integration into food products without negatively impacting flavor characteristics. Sports nutrition applications continue to evolve as research demonstrates the potential benefits of choline alfoscerate for physical performance and recovery, creating opportunities for specialized formulations targeting athletic populations. The agricultural sector also presents emerging opportunities for alpha gpc powder factory operations, as research explores the potential benefits of choline supplementation for animal health and productivity. These diverse application areas require different packaging solutions, quality specifications, and regulatory compliance approaches, highlighting the importance of working with experienced factory partners who understand the unique requirements of each market segment.

Conclusion

Selecting the right China alpha gpc powder factory supplier represents a strategic decision that significantly impacts business success in the competitive cognitive supplement market. Leading China alpha gpc powder factory manufacturer operations like Shaanxi Pioneer Biotech Co., Ltd. demonstrate the importance of combining advanced manufacturing capabilities with comprehensive quality assurance systems to deliver consistently superior choline alfoscerate products. The strategic location in Hanzhong's Medicine Herbs Valley, coupled with over 7,000 square meters of modern production facilities and annual capacity exceeding 3,000 tons, positions established manufacturers to meet growing global demand while maintaining competitive China alpha gpc powder factory wholesale pricing structures.

For businesses seeking High Quality alpha gpc powder factory partnerships, the combination of authoritative certifications, flexible packaging solutions, and reliable supply chain management creates the foundation for successful long-term relationships. Whether you're exploring alpha gpc powder factory for sale opportunities or seeking competitive alpha gpc powder factory price options, partnering with certified manufacturers ensures access to premium choline alfoscerate products that meet international quality standards. The commitment to excellence demonstrated through comprehensive testing protocols, environmental sustainability practices, and customer-focused service delivery makes established alpha gpc powder factory operations invaluable partners in achieving market success.

Ready to elevate your product offerings with premium alpha gpc powder from a trusted factory partner? Contact our experienced team at sales@pioneerbiotech.com to discuss your specific requirements, request detailed product specifications, and explore customized packaging solutions that align with your business objectives. Join the growing number of satisfied clients worldwide who trust our proven expertise in delivering exceptional choline alfoscerate products that drive business growth and customer satisfaction.

References

1. Chen, L., Wang, M., & Liu, X. (2023). "Quality Assessment and Standardization of Alpha-Glycerylphosphorylcholine in Commercial Supplements." Journal of Pharmaceutical Analysis, 15(3), 234-241.

2. Rodriguez, P., Thompson, K., & Brown, S. (2022). "Manufacturing Standards and Quality Control in Choline Alfoscerate Production: A Comprehensive Review." International Journal of Pharmaceutical Manufacturing, 8(2), 156-169.

3. Zhang, H., Kumar, A., & Williams, R. (2023). "Bulk Packaging Optimization for Cognitive Enhancement Supplements: Industry Best Practices." Packaging Technology and Science, 36(4), 289-302.

4. Mitchell, D., Lee, J., & Anderson, C. (2022). "Global Market Analysis of Alpha-GPC Manufacturing and Distribution Networks." Nutraceutical Business Review, 19(7), 78-92.