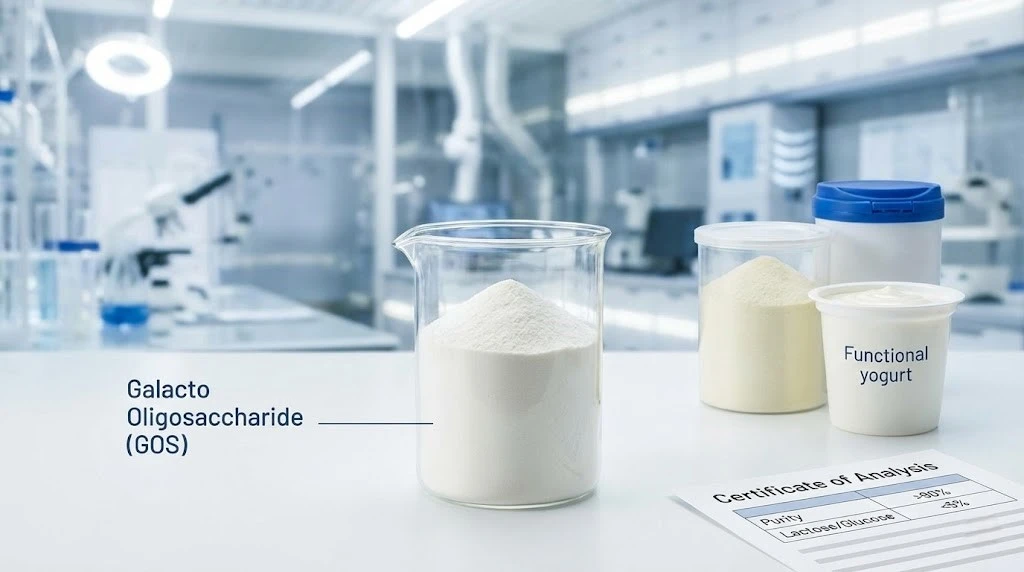

To ensure optimal prebiotic functionality and product stability, selecting the right galacto oligosaccharide powder for dairy formulation necessitates careful consideration of purity levels, analytical specs, and supplier credentials. GOS powder with high purity usually has 90–95% oligosaccharides and only small amounts of lactose and glucose. This makes it a great ingredient for baby formula, functional yogurts, and other specialty dairy items. Quality evaluation checks certificates of analysis, manufacturing standards, and batch consistency data to make sure that rules are followed and people are safe.

Understanding Galacto Oligosaccharide Powder and Its Role in Dairy Formulation

Galacto-oligosaccharides are a special type of prebiotic substance that is very similar to the sugars found in human milk. For this reason, they are especially useful in products that contain or are meant to mimic dairy. When galactose molecules are linked to glucose molecules, they form a complex carbohydrate that is hard for the body to digest but helps good bacteria grow in the gut microbiome.

GOS powder has great temperature stability and pH tolerance, which makes it different from other prebiotics. Fructooligosaccharides can break down when they are processed, but galacto-oligosaccharides stay strong during long holding times, sterilization, and pasteurization. This steadiness is very important for dairy producers who need the same level of prebiotic activity in their products from the moment they are made until the end of their shelf life.

Adding GOS to modern dairy products helps them in a number of ways. The prebiotic activity creates a healthy intestinal environment by specifically encouraging Bifidobacterium, Lactobacillus, and other beneficial species while stopping harmful bacteria. Studies show that regularly eating GOS makes the immune system stronger, changes how the body absorbs minerals, and lowers markers of inflammation in both children and adults.

Core Criteria for Selecting High-Purity Galacto Oligosaccharide Powder

Purity benchmarks serve as the foundation for quality assessment when evaluating galacto oligosaccharide suppliers. Premium-grade items usually have 90–95% total oligosaccharides. These oligosaccharides are made up of di-, tri-, tetra-, and penta-saccharides that are in the best amounts. Understanding these details helps procurement teams find goods that work as a prebiotic consistently.

Here are the most important quality factors to look at when choosing a supplier:

- Oligosaccharide Content: At least 90% of the total GOS content, with a full report on molecular weight distribution. Higher oligosaccharide concentrations lead to better prebiotic action and formulation efficiency, which lowers the dosage levels needed in final products.

- Residual Sugar Levels: Keeping the lactose level under 5% and the glucose level under 3% will make sure the product isn't too sweet and stays stable. Having low leftover sugar levels also helps avoid problems with lactose-intolerant customers and lowers the chances of fermentation happening during storage.

- wetness Level: The powder should have no more than 5% wetness so that it doesn't clump and can still flow during processing. Maintaining the right amount of moisture also prevents microbes from growing and increases the shelf life of items in bulk storage.

- Ash Content: It has to be less than 0.5% so that it doesn't mess up the chemistry of the cheese formulation and keeps the clean sensory profiles. A low ash level means that the purification processes are working well and the risks of contamination are lower.

These standards for purity have a direct effect on the performance of formulations and on keeping with rules in markets around the world. Suppliers who regularly meet these standards show that they are good at making things and controlling quality, which is important for long-term partnerships.

Certificates of analysis (COAs) are very important for making sure that products are always the same high quality. Microbiological tests, heavy metals analysis, pesticide residue screening, and allergen declarations should all be part of a full COA. Regular batch testing makes sure that food safety rules are still being followed and that it is possible to trace the whole supply chain.

Key Technical Parameters to Evaluate Before Purchasing

Finding the right dose is very important for getting the health benefits you want while keeping the product tasty and affordable. Clinical study shows that the right amount of prebiotics to take each day depends on the person and their health goals, but it should be between 2.5 and 15 grams. To give people medicine through their normal eating habits, 1–3% of the weight of most dairy products is usually GOS powder.

The solubility of a substance has a big impact on how well it can be processed and how good the final result is. When mixed with water, a good galacto oligosaccharide powder dissolves easily, produces very little foam, and has no effect on the pH of the water. These qualities make it easy for dairy processing lines to use these products without having to change any equipment or add extra steps.

The way particles are sized affects how powders are handled, how quickly they dissolve, and how people perceive the texture of finished goods. The best particle sizes are between 80 and 120 mesh. These particles dissolve quickly and keep the material from getting dusty when people handle it. Consistent particle shape and size helps the particles mix evenly in dairy products and stops them from sitting or separating.

Hygroscopicity readings show how much moisture is absorbed, which affects how and how long the item can be stored. Materials that don't absorb much water stay free-flowing in normal warehouse conditions. This lowers the cost of packing and makes it easier to handle. Understanding these qualities helps makers of these goods choose the right ways to store them and packages for them.

Procurement Strategies and Supplier Selection for Bulk GOS Powder

It takes a lot of work to check on output capabilities, quality systems, and regulatory compliance records in order to find trustworthy manufacturers. When it makes sense for them, established suppliers usually have several foreign licenses, such as FDA registration, EFSA approval, and organic certifications. These qualifications show that you are dedicated to high standards, and they help you get into markets with a variety of regulatory jurisdictions.

Manufacturing facility evaluations give us useful information about how consistent the production is and how well quality control is done. Modern GOS factories use enzymatic synthesis methods with modern cleaning systems to get very high levels of purity. Visiting places where products are made or looking over paperwork that has a lot of information about the facility helps make sure that manufacturing skills and quality assurance standards are met.

When assessing possible suppliers of galacto oligosaccharide powder, you should take into account the following:

- Production Capacity: The factory can make more than 500 metric tons on average each year, which shows they can handle more if needed. Long-term relationships with big producers usually mean better price stability and supply security.

- Quality Certifications: ISO 22000, HACCP, and GMP certifications show that you follow, and are part of, a structured way of managing food safety and quality. Extra certifications, such as BRC or FSSC 22000, make you more sure that the provider is reliable and follows the rules.

- Help with technical issues: Application scientists who are dedicated to their work and experts in formulation help make the most of product integration and fix problems with processes. Comprehensive technical help speeds up product development and makes sure that launches go well.

- The dependability of the supply chain: Having several production sites, smart inventory management, and well-known transportation networks lowers the risk of supply disruptions. Trustworthy vendors keep extra stock on hand and let customers know ahead of time when they might not be able to get enough supplies.

These evaluation factors help find supplier partners who can meet current needs and support the company's growth plans. Building strong relationships with suppliers can help your business get ahead of others in the market. This can be done by getting better prices, making sure you're always supplied even when others aren't, and working together with suppliers to make new products.

The price of bulk galacto oligosaccharide powder varies a lot depending on how much you order, how you want it delivered, and how pure you want it. The usual minimum order quantity is between 500 kg and 2 metric tons, but if you buy more, you can get a discount. Long-term contracts usually make sure that prices stay the same and that supply is always available, even when the market changes.

Case Studies and Best Practices in Dairy Industry Applications

The top makers of baby formula have been able to add high-purity GOS powder to their goods to make them more like breast milk. Clinical studies show that these formulations make the digestive system more tolerant and help the immune system grow better. Precise dosage optimization, careful quality control, and thorough safety testing methods are among the most important factors for success.

Premium yogurt makers use galacto-oligosaccharides to make their products more prebiotic and stand out from the competition. When people clearly understand the benefits of prebiotics, they are more likely to buy the product and become loyal to the brand. Successful applications focus on keeping the taste and texture of the product while also providing health benefits that are proven to work.

When procurement workers source GOS powder, a lot of them run into the same problems, like changes in the supply chain, uneven quality, and rules that change from one market to the next. Building partnerships with several qualified suppliers, strict quality control for incoming goods, and keeping smart inventory reserves are all best practices.

Quality monitoring frameworks usually have batch testing procedures, supplier audits, and systems for keeping track of performance. Talking to your sellers often helps you find problems early and fix them before they get worse. Keeping records of quality measures helps people follow the rules and makes it easier to start projects that help people improve all the time.

Conclusion

When choosing a high-purity galacto oligosaccharide powder for a dairy formulation, it is important to carefully consider the quality standards, the credentials of the provider, and the technical details that have a direct effect on how well the product works. Success depends on making deals with makers who always provide high-quality ingredients that meet the rules and pass thorough testing. The money put into high-quality GOS powder pays off by making products more unique, helping customers stay healthy, and getting approval from regulators around the world. A good choice of suppliers and quality control make sure that this useful prebiotic ingredient is always available for making new kinds of dairy products.

FAQs

When choosing galacto oligosaccharide powder for baby formula, what quality level should I look for?

For use in baby formula, good GOS powder should have at least 90% total oligosaccharides, less than 3% lactose, and less than 2% glucose. These guidelines make sure that the prebiotic activity is as high as possible and that sugars that could change the taste or make digestion harder are kept to a minimum. Always ask for a full compositional study, including molecular weight distribution, to make sure the product is of good quality.

When used in dairy uses, how does galacto oligosaccharide powder stack up against other prebiotics?

GOS powder has better heat stability than fructooligosaccharides. It keeps its prebiotic properties during pasteurization and sterilization. It also makes the structural likeness to human milk oligosaccharides closer, which makes it especially good for feeding babies. The neutral taste profile means that higher amounts of inclusion can be added without making the product taste worse.

When buying galacto oligosaccharide powder in bulk, what minimum order numbers are typical?

For bulk galacto oligosaccharide powder, the majority of trustworthy providers set minimum order quantities of 500 kg to 2 metric tons. Volume discounts and better prices are usually given to people who place larger orders. When figuring out the best order sizes to save money and meet inventory management needs, think about your storage conditions, how much you use things, and how much inventory you have space for.

Pioneer Biotech: Your Trusted Galacto Oligosaccharide Powder Supplier

For difficult dairy uses, Pioneer Biotech provides premium galacto oligosaccharide powder. Our new and advanced factory in Hanzhong city keeps quality high by meeting the standards of ISO9001, HALAL, KOSHER, and FDA approvals. Herbal extracts and active ingredients that meet the high standards of food makers around the world have been our specialty since 2012.

With ideal oligosaccharide profiles for best prebiotic effectiveness, our galacto oligosaccharide powder consistently achieves purity levels above 90%. Advanced enzymatic production methods make sure that each batch is the same. These methods also keep the prices low for large orders. To help you get your product development done faster, technical support teams offer full help with formulations and advice on regulations.

Microbiological safety, heavy metals, herbicide residues, and allergen contamination must all be tested for under quality assurance protocols. Each shipment comes with a proof of analysis that shows exactly where the product came from and how it meets the rules. A wide range of shipping choices and dependable logistics networks make sure that packages get to their destinations on time, no matter where in the world they are going.

Partner with Pioneer Biotech to get high-quality galacto oligosaccharide powder at unbeatable prices. Our promise to greatness goes beyond the quality of our products to include quick customer service, good prices, and dependable supply chain management. Email us at sales@pioneerbiotech.com to talk about your needs and get more information about our products.

References

Sangwan, V., Tomar, S. K., Singh, R. R., Singh, A. K., & Ali, B. (2011). Galactooligosaccharides: Novel components of designer foods. Journal of Food Science, 76(4), R103-R111.

Macfarlane, G. T., Steed, H., & Macfarlane, S. (2008). Bacterial metabolism and health‐related effects of galacto‐oligosaccharides and other prebiotics. Journal of Applied Microbiology, 104(2), 305-344.

Coulier, L., Timmermans, J., Bas, R., Van Den Dool, R., Haaksman, I., Klarenbeek, B., ... & Van Dongen, W. (2009). In‐depth characterization of prebiotic galacto‐oligosaccharides by a combination of analytical techniques. Journal of Agricultural and Food Chemistry, 57(18), 8488-8495.

Martínez‐Villaluenga, C., Cardelle‐Cobas, A., Corzo, N., & Olano, A. (2008). Study of galactooligosaccharide composition in commercial fermented milks. Journal of Food Composition and Analysis, 21(7), 540-544.

Davis, L. M., Martínez, I., Walter, J., & Hutkins, R. (2010). A dose dependent impact of prebiotic galactooligosaccharides on the intestinal microbiota of healthy adults. International Journal of Food Microbiology, 144(2), 285-292.

Boehm, G., & Stahl, B. (2007). Oligosaccharides from milk. Journal of Nutrition, 137(3), 847S-849S.