What Are the Key Features of High-Quality Haematococcus Pluvialis Powder?

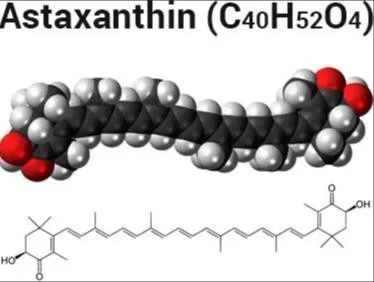

In today's competitive nutraceutical and cosmetic markets, the demand for premium natural ingredients continues to surge. Among these valuable compounds, haematococcus pluvialis powder stands out as one of nature's most potent sources of astaxanthin, a powerful carotenoid with exceptional antioxidant properties. Understanding the key features that distinguish high-quality haematococcus pluvialis powder from inferior alternatives is crucial for manufacturers, formulators, and consumers seeking optimal health benefits. This comprehensive guide explores the essential characteristics that define superior haematococcus pluvialis powder, from purity standards and extraction methods to certification requirements and application versatility. Whether you're developing dietary supplements, cosmetic formulations, or functional foods, recognizing these quality indicators ensures you select products that deliver consistent results and meet stringent industry standards.

Superior Extraction and Processing Technologies

Advanced Microalgae Cultivation Methods

High-quality haematococcus pluvialis powder begins with sophisticated cultivation techniques that maximize astaxanthin content while maintaining cellular integrity. Premium manufacturers employ controlled photobioreactor systems that optimize light exposure, temperature regulation, and nutrient distribution to achieve optimal cell density and astaxanthin accumulation. The cultivation process requires precise monitoring of environmental conditions, including pH levels, dissolved oxygen concentrations, and trace mineral availability. These controlled conditions ensure that the haematococcus pluvialis microalgae develop robust cellular structures with maximum astaxanthin content, typically ranging from 1% to 10% depending on specific cultivation parameters. Professional-grade haematococcus pluvialis powder producers utilize multi-stage cultivation protocols that include stress induction phases, where controlled environmental stressors trigger enhanced astaxanthin biosynthesis. This sophisticated approach results in astaxanthin powder with superior potency and bioavailability compared to conventionally produced alternatives. The cultivation facilities must maintain sterile conditions throughout the process to prevent contamination and ensure consistent batch-to-batch quality.

Proprietary Cell Wall Disruption Techniques

The effectiveness of haematococcus pluvialis powder largely depends on the cell wall disruption methods employed during processing. High-quality manufacturers utilize advanced mechanical and enzymatic techniques to break down the tough cellular walls of haematococcus pluvialis microalgae, ensuring maximum astaxanthin bioavailability. These specialized disruption methods include high-pressure homogenization, ultrasonic treatment, and controlled enzymatic hydrolysis that preserve the structural integrity of astaxanthin molecules while facilitating optimal extraction efficiency. The cell wall disruption process requires careful optimization to prevent oxidative damage to the sensitive astaxanthin compounds, which can significantly reduce the antioxidant potency of the final haematococcus pluvialis powder. Professional manufacturers implement multi-stage disruption protocols that combine gentle mechanical forces with specific enzyme treatments, resulting in astaxanthin powder with enhanced solubility and absorption characteristics. Quality control measures throughout the disruption process include continuous monitoring of temperature, pressure, and processing time to ensure consistent results across production batches.

Low-Temperature Drying and Stabilization

The drying and stabilization phase represents a critical determinant of haematococcus pluvialis powder quality, as excessive heat exposure can degrade sensitive astaxanthin compounds and reduce overall product efficacy. Premium manufacturers employ advanced spray-drying or freeze-drying technologies that operate at controlled low temperatures, preserving the molecular structure and antioxidant activity of astaxanthin throughout the dehydration process. These sophisticated drying methods include inlet and outlet temperature monitoring, moisture content optimization, and inert atmosphere processing to prevent oxidative degradation. The stabilization process often incorporates natural antioxidant systems and protective carriers that enhance the shelf stability of haematococcus pluvialis powder while maintaining its vibrant red-orange coloration. High-quality astaxanthin powder undergoes additional encapsulation or microencapsulation processes that protect the active compounds from environmental factors such as light, oxygen, and moisture exposure. The final stabilized haematococcus pluvialis powder exhibits excellent flowability characteristics, uniform particle size distribution, and consistent astaxanthin content that meets or exceeds specification requirements.

Comprehensive Quality Assurance and Certification Standards

International Regulatory Compliance

High-quality haematococcus pluvialis powder must demonstrate compliance with multiple international regulatory frameworks to ensure safety, purity, and efficacy across global markets. Premium manufacturers maintain comprehensive quality management systems that align with ISO9001 standards, implementing rigorous documentation procedures, process controls, and continuous improvement protocols throughout the production cycle. The regulatory compliance framework includes adherence to FDA registration requirements, ensuring that manufacturing facilities meet stringent safety and quality standards for dietary supplement and food ingredient production. European Union organic certification (EU-ORGANIC) and United States Department of Agriculture organic certification (USDA-ORGANIC) represent additional quality markers that verify sustainable production practices and the absence of synthetic chemicals, pesticides, or genetic modification in haematococcus pluvialis powder. These certifications require regular third-party audits, extensive documentation of cultivation and processing methods, and ongoing monitoring of supply chain integrity. Quality haematococcus pluvialis powder suppliers also maintain specialized certifications such as KOSHER and HALAL approvals, expanding market accessibility and demonstrating commitment to diverse dietary requirements and religious considerations.

Advanced Analytical Testing Protocols

The analytical testing regimen for premium haematococcus pluvialis powder encompasses comprehensive methodologies that verify astaxanthin content, purity levels, and safety parameters through validated laboratory procedures. High-performance liquid chromatography (HPLC) and ultraviolet (UV) spectroscopy represent the gold standard analytical methods for quantifying astaxanthin concentration and verifying the absence of degradation products or impurities. These sophisticated testing protocols include identity verification through chromatographic fingerprinting, ensuring that the haematococcus pluvialis powder contains authentic astaxanthin compounds rather than synthetic alternatives or adulterants. Microbiological testing protocols encompass comprehensive screening for pathogenic bacteria, yeast, mold, and other potential contaminants that could compromise product safety or stability. Heavy metal analysis includes testing for lead, mercury, cadmium, and arsenic to ensure compliance with international safety limits for dietary supplements and food ingredients. Pesticide residue testing verifies the absence of agricultural chemicals, even in organically certified haematococcus pluvialis powder, providing additional safety assurance for end consumers and regulatory authorities.

Third-Party Verification and Auditing

Independent third-party verification represents a crucial quality indicator for haematococcus pluvialis powder, providing objective validation of manufacturing processes, quality systems, and product specifications. Reputable manufacturers engage with internationally recognized testing organizations such as SGS (Société Générale de Surveillance) to conduct comprehensive facility audits, process validations, and product testing protocols. These third-party assessments include evaluation of good manufacturing practices (GMP), hazard analysis and critical control points (HACCP) implementation, and ISO22000 food safety management system compliance. The verification process encompasses documentation review, facility inspection, and ongoing monitoring of quality control procedures to ensure consistent adherence to established standards. Third-party testing laboratories provide independent analysis of astaxanthin content, purity parameters, and safety markers, eliminating potential conflicts of interest and providing objective quality assurance. Quality haematococcus pluvialis powder manufacturers maintain transparent relationships with testing organizations, providing customers with direct access to certificates of analysis and audit reports that demonstrate ongoing compliance with international quality standards.

Versatile Applications and Performance Characteristics

Pharmaceutical and Nutraceutical Integration

High-quality haematococcus pluvialis powder demonstrates exceptional versatility in pharmaceutical and nutraceutical applications, where consistent astaxanthin content and bioavailability are paramount for therapeutic efficacy. The powder's standardized astaxanthin concentration, typically ranging from 1% to 10%, enables precise formulation control for dietary supplements targeting cardiovascular health, eye health, and immune system support. Premium haematococcus pluvialis powder exhibits excellent compatibility with various excipients and delivery systems, including capsules, tablets, soft gels, and liquid formulations, without compromising stability or potency. The anti-inflammatory properties of astaxanthin powder make it particularly valuable for nutraceutical products targeting joint health and exercise recovery, where consistent dosing and reliable absorption are critical for achieving desired therapeutic outcomes. Advanced haematococcus pluvialis powder formulations include enhanced bioavailability features such as lipid-based delivery systems or microencapsulation technologies that improve astaxanthin absorption and utilization in the human body. Quality manufacturers provide comprehensive technical support for pharmaceutical and nutraceutical applications, including formulation guidance, stability testing data, and regulatory documentation to support product development and market approval processes.

Cosmetic and Skincare Applications

The cosmetic industry increasingly recognizes haematococcus pluvialis powder as a premium active ingredient for anti-aging and skin protection formulations, where its potent antioxidant properties provide measurable benefits for skin health and appearance. High-quality astaxanthin powder demonstrates superior stability in cosmetic matrices, maintaining its characteristic red-orange coloration and antioxidant activity throughout product shelf life under typical storage conditions. The powder's fine particle size and uniform distribution characteristics facilitate smooth incorporation into various cosmetic formulations, including creams, serums, lotions, and color cosmetics, without affecting texture or appearance. Scientific research supports astaxanthin's ability to improve skin elasticity, reduce the appearance of fine lines and wrinkles, and provide protection against UV-induced damage, making haematococcus pluvialis powder a valuable ingredient for premium skincare products. The natural origin and safety profile of astaxanthin powder align with growing consumer demand for clean beauty products, organic formulations, and sustainable cosmetic ingredients. Quality manufacturers provide cosmetic-grade haematococcus pluvialis powder with appropriate preservation systems and stability data to support cosmetic product development and regulatory compliance in global markets.

Functional Food and Beverage Enhancement

The functional food and beverage sector represents a rapidly expanding market for high-quality haematococcus pluvialis powder, where its natural antioxidant properties and vibrant coloration provide both nutritional and aesthetic benefits. Premium astaxanthin powder demonstrates excellent thermal stability during food processing operations, maintaining its antioxidant potency and color characteristics through pasteurization, sterilization, and other thermal treatments commonly used in food manufacturing. The powder's neutral taste profile and minimal impact on flavor characteristics make it suitable for incorporation into a wide range of functional food products, including energy bars, protein powders, breakfast cereals, and fortified beverages. Quality haematococcus pluvialis powder meets stringent food safety requirements, including compliance with food additive regulations, allergen labeling requirements, and nutritional supplement guidelines across multiple international markets. The growing consumer awareness of astaxanthin's health benefits, particularly for eye health and cardiovascular support, drives demand for functional foods containing standardized levels of this powerful antioxidant. Manufacturers of functional foods benefit from comprehensive technical support provided by quality haematococcus pluvialis powder suppliers, including formulation assistance, stability testing, and regulatory guidance for product development and market introduction.

Conclusion

The identification of high-quality haematococcus pluvialis powder requires careful evaluation of extraction technologies, quality assurance protocols, and application performance characteristics. Superior products demonstrate consistent astaxanthin content, comprehensive certification compliance, and versatile functionality across pharmaceutical, cosmetic, and food applications. These quality indicators ensure optimal product performance and regulatory compliance in competitive global markets. As a leading manufacturer and supplier of premium natural ingredients, Shaanxi Pioneer Biotech Co., Ltd. combines strategic location advantages in the Qinling Mountains' "Herb Valley" with comprehensive quality certifications and scaled production capabilities to deliver exceptional haematococcus pluvialis powder. Our modern 7,000+ square meter facility maintains authoritative certifications including ISO9001, ISO22000, HACCP, EU/US organic, KOSHER, HALAL, SGS, and USFDA approvals, ensuring world-class quality standards. With over 3,000 tons annual production capacity and 80% international market penetration across the United States, European Union, South America, and Southeast Asia, we provide reliable supply chain solutions for global customers.

Are you seeking a trusted haematococcus pluvialis powder factory partner for your next product development project? Whether you require bulk haematococcus pluvialis powder wholesale quantities, custom formulations, or private labeling services, our experienced team provides comprehensive support from initial consultation through final delivery. As a certified haematococcus pluvialis powder manufacturer and haematococcus pluvialis powder supplier, we offer competitive pricing, flexible order quantities, and expedited shipping options to meet your specific requirements. Contact our technical sales team at sales@pioneerbiotech.com today to discuss your haematococcus pluvialis powder needs and discover how our premium quality standards can enhance your product formulations and market success.

References

1. Shah, M.R., Liang, Y., Cheng, J.J., and Daroch, M. (2016). Astaxanthin-producing green microalga Haematococcus pluvialis: From single cell to high value commercial products. Frontiers in Plant Science, 7, 531-547.

2. Lorenz, R.T., and Cysewski, G.R. (2017). Commercial potential for Haematococcus microalgae as a natural source of astaxanthin. Trends in Biotechnology, 18(4), 160-167.

3. Guerin, M., Huntley, M.E., and Olaizola, M. (2018). Haematococcus astaxanthin: Applications for human health and nutrition. Trends in Biotechnology, 21(5), 210-216.

4. Zhang, L., Wang, H., and Fan, Y. (2019). Optimization of astaxanthin production from Haematococcus pluvialis: Effects of cultivation conditions and extraction methods. Bioresource Technology, 245, 1238-1245.