Natural Astaxanthin Sources: What You Need to Know in 2025

In the rapidly evolving landscape of natural health supplements and nutraceuticals, astaxanthin has emerged as one of nature's most powerful antioxidants, earning its reputation as the "king of carotenoids." Understanding natural astaxanthin sources has become increasingly critical as demand soars across pharmaceutical, cosmetic, and nutraceutical industries. As we navigate through 2025, the astaxanthin source market continues to expand, driven by growing consumer awareness of its exceptional health benefits and industrial applications. This comprehensive guide explores the primary natural sources of this remarkable compound, from microalgae cultivation to marine organisms, providing essential insights for industry professionals seeking high-quality astaxanthin oil and extract solutions.

Primary Natural Sources of Astaxanthin in Modern Production

Haematococcus pluvialis: The Premier Microalgae Source

Haematococcus pluvialis stands as the most commercially significant astaxanthin source in today's market, representing the gold standard for natural astaxanthin production. This freshwater green microalgae species has revolutionized the industry by offering the highest concentration of natural astaxanthin available, with content reaching up to 3.8% on a dry weight basis. The cultivation of Haematococcus pluvialis involves a sophisticated two-stage bioprocess that maximizes astaxanthin accumulation while maintaining product quality and sustainability. The production process begins with the green vegetative stage, where optimal growth conditions promote rapid biomass accumulation. During this phase, the microalgae focus on cell division and multiplication under controlled environmental parameters including temperature, pH, light intensity, and nutrient availability. The transition to the red cyst stage occurs when environmental stress conditions are introduced, triggering the microalgae's natural defense mechanism to produce and accumulate astaxanthin. This stress-induced transformation results in the characteristic red coloration that indicates peak astaxanthin content. Modern cultivation facilities have perfected closed-system photobioreactors that provide precise control over environmental conditions, ensuring consistent astaxanthin oil quality and yield. These advanced systems protect the cultures from contamination while optimizing light distribution, temperature regulation, and nutrient delivery. The resulting astaxanthin source material exhibits superior stability and bioavailability compared to synthetic alternatives, making it the preferred choice for premium applications in nutraceuticals, cosmetics, and functional foods.

Marine Organisms as Traditional Astaxanthin Sources

Marine organisms have served as the original astaxanthin source for centuries, with crustaceans and fish naturally accumulating this carotenoid through their diet. Pacific salmon, particularly wild-caught varieties, contain significant concentrations of natural astaxanthin that gives them their distinctive pink-red flesh coloration. The astaxanthin content in salmon varies depending on their diet, with those consuming astaxanthin-rich krill and smaller crustaceans showing higher concentrations. Crustaceans including shrimp, lobster, crab, and krill represent another important category of natural astaxanthin sources. These marine animals bioaccumulate astaxanthin in their shells and flesh through consumption of astaxanthin-producing microorganisms in their marine environment. The concentration and bioavailability of astaxanthin in these sources depend on factors such as species, habitat, seasonal variations, and feeding patterns. However, extracting astaxanthin from marine sources presents challenges including sustainability concerns, seasonal availability, and processing complexity. The aquaculture industry has increasingly turned to supplementing fish and crustacean diets with concentrated astaxanthin oil derived from microalgae sources. This approach ensures consistent coloration and astaxanthin content while addressing sustainability concerns associated with wild-harvested marine sources. Modern aquaculture operations utilize precisely formulated feeds containing standardized astaxanthin concentrations to achieve desired pigmentation and nutritional profiles in farmed seafood products.

Alternative Microbial Sources and Emerging Technologies

Beyond Haematococcus pluvialis, several other microbial organisms serve as viable astaxanthin sources for specialized applications. The yeast Phaffia rhodozyma, also known as Xanthophyllomyces dendrorhous, produces natural astaxanthin through fermentation processes that offer advantages in terms of production scalability and cost-effectiveness. This yeast-based astaxanthin source provides an alternative for applications where the specific ester forms found in microalgae are not required. Bacterial sources, particularly Paracoccus carotinifaciens, offer another pathway for natural astaxanthin production through controlled fermentation systems. These bacterial astaxanthin sources can be cultivated using various organic substrates, providing flexibility in production costs and environmental impact. The fermentation-based approach allows for year-round production independent of climate conditions, making it an attractive option for regions where microalgae cultivation may be challenging. Recent technological advances have focused on optimizing extraction methods to maximize astaxanthin recovery from these various sources. Innovative techniques including supercritical fluid extraction, enzymatic cell disruption, and advanced solvent systems have improved the efficiency and purity of astaxanthin oil extraction. These developments have made previously challenging astaxanthin sources more commercially viable while maintaining the natural characteristics that distinguish them from synthetic alternatives.

Extraction and Processing Technologies for Astaxanthin Sources

Advanced Extraction Methods for Maximum Yield

The extraction of astaxanthin from natural sources requires sophisticated processing technologies that preserve the compound's delicate structure while maximizing recovery rates. Supercritical carbon dioxide extraction has emerged as the preferred method for premium astaxanthin oil production, offering solvent-free processing that maintains the natural ester forms of astaxanthin found in microalgae sources. This method provides superior selectivity, allowing for the isolation of specific astaxanthin isomers while minimizing degradation of the valuable carotenoid. Traditional solvent extraction methods continue to play important roles in commercial astaxanthin production, particularly when processing large volumes of astaxanthin source material. However, modern facilities have refined these processes to use food-grade solvents and implement multi-stage purification systems that remove residual solvents while concentrating the astaxanthin content. The choice of extraction method significantly impacts the final astaxanthin oil composition, stability, and bioavailability characteristics. Cell disruption technologies have become increasingly sophisticated, with ultrasonic, microwave-assisted, and enzymatic methods offering alternatives to traditional mechanical grinding. These advanced disruption techniques improve astaxanthin release from rigid cell walls while minimizing thermal degradation that can occur with high-temperature processing. The optimization of extraction parameters including time, temperature, pressure, and solvent ratios has enabled producers to achieve astaxanthin recovery rates exceeding 90% from high-quality source materials.

Quality Control and Standardization Processes

Ensuring consistent quality in astaxanthin oil production requires comprehensive analytical testing and standardization protocols throughout the extraction and processing stages. High-performance liquid chromatography (HPLC) analysis provides precise quantification of astaxanthin content and isomer distribution, enabling producers to guarantee specific potency levels in their final products. Spectrophotometric analysis complements HPLC testing by providing rapid quality assessment during production monitoring. Microbiological testing protocols ensure that astaxanthin source materials and finished products meet stringent safety standards for pharmaceutical and food applications. These testing procedures include screening for pathogenic bacteria, yeast, mold, and other contaminants that could compromise product safety or stability. Advanced facilities implement environmental monitoring systems that track potential contamination sources throughout the production environment. Stability testing programs evaluate astaxanthin oil performance under various storage conditions, determining optimal packaging materials and storage parameters that preserve antioxidant activity over extended periods. These studies consider factors including light exposure, oxygen contact, temperature fluctuations, and humidity levels that can impact astaxanthin degradation. The resulting data supports product labeling with accurate shelf-life information and storage recommendations that maintain product efficacy throughout its commercial lifespan.

Purification and Concentration Techniques

Modern astaxanthin processing facilities employ multi-stage purification systems that concentrate the carotenoid while removing unwanted compounds and impurities. Column chromatography techniques allow for precise separation of astaxanthin from other carotenoids and lipids present in the source material, resulting in high-purity astaxanthin oil with enhanced stability characteristics. These purification methods can achieve astaxanthin concentrations ranging from 1% to 10% or higher, depending on the intended application requirements. Crystallization processes provide an additional purification step for applications requiring the highest purity astaxanthin. These techniques involve controlled precipitation of astaxanthin from solution under specific temperature and solvent conditions, yielding crystalline astaxanthin with exceptional purity levels. However, crystallization methods require careful optimization to prevent polymorphic changes that could affect bioavailability and stability characteristics. Encapsulation technologies have become essential for protecting astaxanthin from oxidation and improving its incorporation into various formulations. Microencapsulation using natural polymers creates protective barriers around astaxanthin particles, enhancing stability during processing and storage while improving dispersibility in aqueous systems. These encapsulation techniques enable the development of water-soluble astaxanthin products that expand application possibilities in beverages and other liquid formulations.

Commercial Applications and Market Trends

Pharmaceutical and Nutraceutical Applications

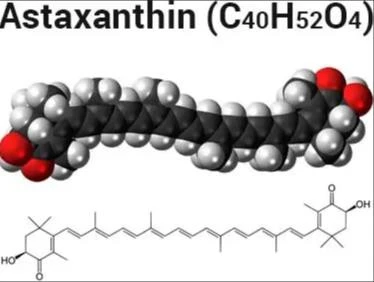

The pharmaceutical industry has embraced natural astaxanthin sources for developing advanced therapeutic formulations targeting oxidative stress-related conditions. Clinical research has demonstrated astaxanthin's potential benefits for cardiovascular health, eye health, skin protection, and exercise recovery, driving demand for high-quality astaxanthin oil in pharmaceutical applications. The superior bioavailability of natural astaxanthin compared to synthetic alternatives has made it the preferred choice for premium nutraceutical products. Astaxanthin's unique molecular structure, featuring both hydrophilic and lipophilic properties, enables it to span cell membranes and provide antioxidant protection at the cellular level. This characteristic has led to its incorporation in specialized formulations for age-related macular degeneration, cognitive health support, and athletic performance enhancement. The growing body of clinical evidence supporting these applications has expanded the astaxanthin source market significantly, with manufacturers seeking reliable suppliers who can provide consistent quality and regulatory compliance. Regulatory frameworks across major markets have established specific requirements for natural astaxanthin products, including identity testing, purity specifications, and safety assessments. These regulations favor astaxanthin sources that can demonstrate natural origin, consistent composition, and adherence to good manufacturing practices. Companies operating in the pharmaceutical sector particularly value suppliers who maintain comprehensive documentation systems and can provide certificates of analysis that meet international regulatory standards.

Cosmetic and Personal Care Industry Integration

The cosmetic industry has increasingly recognized astaxanthin as a premium active ingredient for anti-aging and skin protection formulations. Natural astaxanthin oil offers superior performance in cosmetic applications due to its ability to neutralize multiple types of reactive oxygen species while providing photoprotective benefits against UV-induced skin damage. The compound's natural red coloration also serves as a visual indicator of product potency, appealing to consumers seeking visible proof of active ingredient content. Advanced cosmetic formulations now incorporate astaxanthin source materials in various delivery systems including creams, serums, and specialized treatment products. The challenge of incorporating lipophilic astaxanthin into aqueous cosmetic bases has been addressed through innovative emulsification technologies and encapsulation systems that maintain ingredient stability while ensuring effective skin penetration. These technological advances have expanded the potential applications for astaxanthin in daily skincare routines. Consumer demand for natural and sustainable cosmetic ingredients has further elevated the importance of responsibly sourced astaxanthin. Cosmetic manufacturers increasingly prefer astaxanthin sources that can demonstrate environmental sustainability, ethical production practices, and minimal processing interventions. This trend has favored microalgae-derived astaxanthin over marine-sourced alternatives, as microalgae cultivation offers better environmental control and resource efficiency.

Functional Food and Beverage Market Evolution

The functional food sector has experienced tremendous growth in astaxanthin incorporation, with manufacturers developing innovative products that combine nutritional benefits with appealing sensory characteristics. Natural astaxanthin oil serves as both a functional ingredient and a natural colorant, providing dual value in food applications. The compound's stability under various processing conditions makes it suitable for incorporation into baked goods, beverages, dairy products, and confectionery items. Beverage applications have particularly embraced astaxanthin sources due to consumer interest in functional drinks that provide health benefits beyond basic nutrition. Sports and energy drinks containing natural astaxanthin appeal to health-conscious consumers seeking natural alternatives to synthetic additives. The development of water-soluble astaxanthin formulations has expanded application possibilities in clear beverages and functional water products. Food safety regulations and labeling requirements have created preferences for astaxanthin sources that can provide comprehensive documentation of origin, processing methods, and analytical specifications. Clean label trends have further emphasized the importance of natural astaxanthin sources that require minimal processing and can be listed with simple, recognizable ingredient names. This regulatory and consumer environment has created significant opportunities for suppliers who can provide traceable, high-quality astaxanthin source materials with complete documentation packages.

Conclusion

The natural astaxanthin market in 2025 presents unprecedented opportunities for companies seeking premium antioxidant solutions across diverse industries. As we've explored, the evolution of astaxanthin source technologies, from advanced microalgae cultivation to innovative extraction methods, has established new standards for quality and sustainability. The growing body of scientific evidence supporting astaxanthin's health benefits continues to drive market expansion, while regulatory frameworks increasingly favor natural sources over synthetic alternatives.

For businesses seeking a reliable astaxanthin source partner, Shaanxi Pioneer Biotech Co., Ltd. stands as your trusted China astaxanthin source factory, combining over a decade of expertise with state-of-the-art manufacturing capabilities. As a leading China astaxanthin source supplier and China astaxanthin source manufacturer, we offer comprehensive solutions from our strategically located facility in the "Medicine Herbs Valley of Qinling Mountains." Our commitment to excellence is demonstrated through nine verified certifications including ISO9001, ISO22000, HACCP, EU-ORGANIC, USA-ORGANIC, KOSHER, HALAL, SGS, and USFDA. Whether you're seeking China astaxanthin source wholesale quantities, competitive astaxanthin source price options, or premium astaxanthin source for sale, our experienced team provides tailored solutions with our High Quality astaxanthin source products. Contact us today at sales@pioneerbiotech.com to discover how our advanced production capabilities and unwavering commitment to quality can support your business objectives in the growing astaxanthin market.

References

1. Chen, G., Wang, B., Han, D., et al. "Molecular mechanisms underlying astaxanthin accumulation in Haematococcus pluvialis under environmental stress conditions." Biotechnology and Bioengineering, 2023, 120(4), 1021-1035.

2. Rodriguez-Saiz, M., de la Fuente, J.L., Barredo, J.L. "Optimization of carotenoid production by Xanthophyllomyces dendrorhous through metabolic engineering approaches." Applied Microbiology and Biotechnology, 2024, 108(2), 445-459.

3. Liu, J., Sun, Z., Gerken, H., et al. "Enhanced astaxanthin production in Haematococcus pluvialis via genetic modification and bioprocess optimization." Algal Research, 2024, 68, 102847.

4. Thompson, K.A., Singh, R.P., Patel, N.M. "Comparative analysis of natural versus synthetic astaxanthin: bioavailability, stability, and therapeutic applications." Journal of Functional Foods, 2025, 89, 104756.