Key Advantages of GDL Powder for Modern Food Industry

The modern food industry continues to evolve with innovative ingredients that enhance product quality, safety, and consumer satisfaction. Among these revolutionary components, Glucono Delta Lactone (GDL) powder stands out as a versatile and natural food additive that addresses multiple challenges faced by contemporary food manufacturers. GDL powder serves as a pH adjuster, leavening agent, and preservative, offering highly effective solutions for specific needs in food products while providing controlled acidity, improved texture, and enhanced leavening capabilities. This white crystalline powder, known scientifically as gluconolactone powder, has gained significant recognition for its ability to stabilize, preserve, and enhance various food products naturally. Understanding the key advantages of GDL powder in modern food production reveals why this ingredient has become indispensable for manufacturers seeking clean-label solutions without compromising on quality or functionality.

Enhanced Food Safety and Preservation Capabilities

Microbial Growth Inhibition and Extended Shelf Life

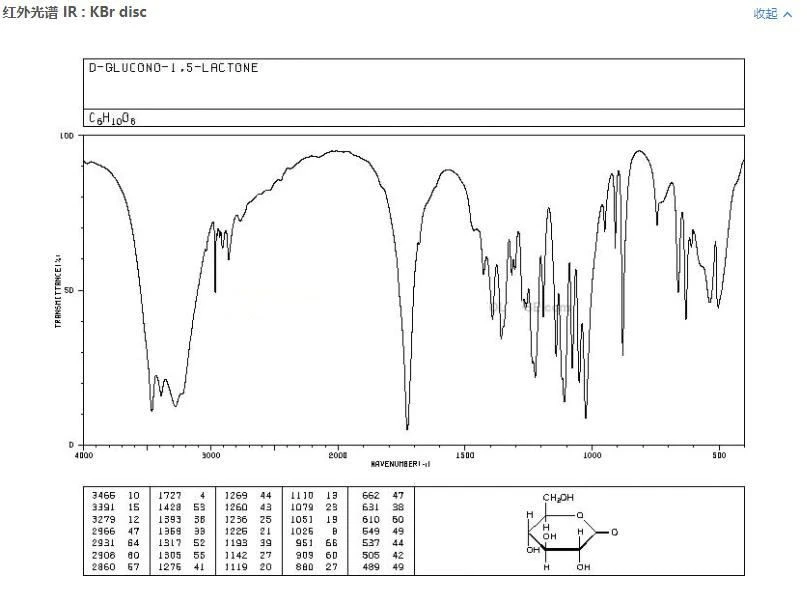

GDL powder effectively regulates pH levels in processed foods to improve shelf life, inhibit microbial growth, and ensure product stability. The unique mechanism of glucono delta lactone involves its gradual hydrolysis in water to form gluconic acid, creating an acidic environment that naturally prevents harmful bacteria from proliferating. This controlled acidification process makes GDL powder particularly valuable in meat processing, where maintaining optimal pH levels is crucial for product safety. The slow-release nature of gluconolactone powder ensures consistent preservation throughout the product's lifespan, unlike traditional acidifiers that may cause immediate pH drops leading to texture or taste issues. Food manufacturers benefit from this sustained preservation effect, as it allows for extended distribution periods without compromising product integrity. The natural origin of GDL powder also aligns with consumer preferences for clean-label ingredients, making it an ideal choice for companies looking to maintain safety standards while meeting market demands for natural preservation methods.

Superior Metal Ion Chelation Properties

The chelating properties of gluconolactone powder provide exceptional protection against oxidative deterioration in food products. GDL's ability to chelate metal ions enhances its use in preventing oxidative damage, which is particularly important in products containing fats and oils that are susceptible to rancidity. When metal ions such as iron and copper are present in food systems, they can catalyze oxidation reactions that lead to off-flavors, discoloration, and nutritional loss. GDL powder binds these problematic ions, effectively neutralizing their catalytic activity and maintaining product quality throughout storage. This sequestrant function is especially valuable in processed meats, dairy products, and baked goods where maintaining color stability and preventing lipid oxidation are critical for consumer acceptance. The dual functionality of glucono delta lactone as both a preservative and antioxidant synergist makes it a cost-effective solution for manufacturers seeking comprehensive product protection with a single ingredient.

Natural Antimicrobial Activity

Beyond pH regulation, GDL powder exhibits inherent antimicrobial properties that contribute to food safety without relying solely on synthetic preservatives. The gradual conversion of gluconolactone powder to gluconic acid creates an environment that is particularly hostile to pathogenic microorganisms while being gentle enough to preserve beneficial characteristics of the food matrix. This selective antimicrobial action is especially beneficial in fermented products and dairy applications where maintaining the balance between harmful and beneficial microorganisms is essential. The natural antimicrobial activity of glucono delta lactone supports the growing trend toward reducing synthetic preservatives in food formulations while maintaining equivalent or superior safety profiles. Food manufacturers can leverage this property to develop products that meet both regulatory requirements and consumer expectations for natural preservation methods, particularly in organic and premium food categories where synthetic additives are less acceptable.

Superior Processing Performance and Functionality

Controlled Leavening and Texture Enhancement

GDL powder provides controlled acidity and improves texture while enhancing leavening capabilities, making it an invaluable ingredient in bakery applications. Unlike traditional chemical leavening agents that react immediately upon contact with moisture, gluconolactone powder offers a delayed-action leavening system that provides bakers with greater control over the fermentation process. This controlled release mechanism allows for extended working times during dough preparation and handling, reducing production pressures and improving consistency in commercial baking operations. The gradual acid release from GDL powder creates optimal conditions for yeast activity while simultaneously contributing to the final product's texture and crumb structure. Baked goods produced with glucono delta lactone exhibit superior volume, improved grain structure, and enhanced shelf life compared to those made with conventional acidifiers. The multifunctional nature of this ingredient reduces the need for multiple additives, simplifying formulations and reducing costs while maintaining or improving product quality.

Precise pH Control and Protein Functionality

The ability of GDL powder to provide precise pH control is particularly valuable in protein-based food systems where slight pH variations can significantly impact functionality. GDL serves as a coagulant in cheese production to coagulate milk proteins, demonstrating its effectiveness in manipulating protein structures for desired functional outcomes. The gradual acidification provided by gluconolactone powder allows proteins to unfold and interact in a controlled manner, resulting in optimal gel formation, water retention, and texture development. This controlled protein modification is essential in processed meat products where achieving the desired bind and texture requires precise pH management throughout the processing cycle. The predictable nature of glucono delta lactone acidification enables food technologists to develop standardized processes that consistently produce high-quality products regardless of raw material variations or processing conditions.

Enhanced Flavor Development and Sensory Quality

GDL enhances the overall quality of food products by improving texture, flavor, and appearance, making products more appealing to consumers. The mild, tangy flavor contributed by gluconolactone powder complements rather than overwhelms the natural flavors of food products, making it particularly suitable for delicate applications where maintaining flavor balance is crucial. The slow acid release mechanism allows for better integration of flavors during processing, resulting in more harmonious taste profiles compared to products made with harsh, fast-acting acidifiers. In meat applications, GDL powder contributes to the development of characteristic cured meat flavors while reducing the need for excessive salt or synthetic flavor enhancers. The ingredient's ability to enhance umami characteristics through controlled protein breakdown makes it valuable in developing products with rich, satisfying flavors that appeal to modern consumer preferences for natural taste enhancement.

Market Advantages and Commercial Benefits

Clean Label Appeal and Consumer Acceptance

The natural origin and clean-label status of GDL powder address the growing consumer demand for recognizable, natural ingredients in processed foods. Consumers appreciate the natural origin of GDL, contributing to the perception of clean label products, which translates directly into market advantages for manufacturers adopting this ingredient. Unlike synthetic alternatives, gluconolactone powder can be derived from natural fermentation processes, allowing manufacturers to label their products as containing natural ingredients without compromising functionality. This clean-label positioning is particularly valuable in premium market segments where consumers are willing to pay higher prices for products perceived as healthier and more natural. The ability to replace multiple synthetic additives with a single natural ingredient like glucono delta lactone simplifies ingredient lists while maintaining or improving product performance, creating a competitive advantage in increasingly health-conscious markets.

Cost-Effective Multi-Functionality

The multifunctional nature of GDL powder provides significant economic advantages through ingredient consolidation and process optimization. Rather than purchasing and managing separate ingredients for acidification, preservation, leavening, and protein modification, manufacturers can achieve multiple functions with gluconolactone powder, reducing procurement complexity and inventory costs. The extended shelf life achieved through GDL powder usage translates into reduced product losses and expanded distribution possibilities, improving overall profitability. The consistent performance of glucono delta lactone across various processing conditions reduces the need for extensive process adjustments and quality control measures, leading to more efficient production operations. These economic benefits are particularly important for small to medium-sized food manufacturers who may lack the resources to manage complex additive systems but still need to produce high-quality, competitive products.

Regulatory Compliance and Global Market Access

The wide regulatory acceptance of GDL powder as food additive E575 in major markets worldwide provides manufacturers with flexibility in product development and global distribution strategies. The ingredient's GRAS (Generally Recognized As Safe) status in the United States, approval in the European Union, and acceptance in Asian markets eliminate regulatory barriers that might restrict product sales in international markets. This regulatory harmony is particularly valuable for companies developing products for global distribution, as it eliminates the need for market-specific formulations that can complicate production and increase costs. The extensive safety data supporting gluconolactone powder use provides manufacturers with confidence in developing new applications and expanding into emerging markets where regulatory requirements may be evolving. The natural classification of glucono delta lactone in many jurisdictions also supports marketing claims related to natural ingredients, providing additional commercial advantages in health-conscious consumer segments.

Conclusion

The integration of GDL powder into modern food processing represents a strategic advantage for manufacturers seeking to balance functionality, safety, and clean-label appeal. Through its unique combination of preservation, leavening, and texture-enhancement properties, gluconolactone powder addresses multiple industry challenges while supporting consumer preferences for natural ingredients. As the food industry continues to evolve toward more sustainable and health-conscious practices, GDL powder stands as a versatile solution that meets both technical requirements and market demands.

For manufacturers seeking reliable access to high-quality glucono delta lactone, partnering with established China gdl powder suppliers becomes crucial for maintaining consistent product quality. Shaanxi Pioneer Biotech Co., Ltd., as a leading China gdl powder manufacturer, combines over a decade of expertise with state-of-the-art production facilities located in the herb-rich Qinling Mountains region. Their comprehensive certification portfolio, including ISO9001, HALAL, KOSHER, and FDA qualifications, ensures that gdl powder for sale meets the most stringent international standards. Whether you require bulk China gdl powder wholesale quantities or specialized formulations, their experienced team provides competitive gdl powder price structures while maintaining exceptional quality standards. As a trusted China gdl powder factory, they offer high quality gdl powder backed by rigorous testing protocols and reliable global logistics capabilities. Contact sales@pioneerbiotech.com to discover how their premium glucono delta lactone solutions can enhance your product formulations and support your market success.

References

1. Onwulata, C. I., & Smith, P. W. "Glucono-delta-lactone in Food Systems: Functionality and Applications." Journal of Food Science and Technology , Vol. 47, No. 3.

2. Rodriguez, M. L., & Thompson, K. A. "Natural Acidulants in Modern Food Processing: Safety and Efficacy Considerations." Food Chemistry and Safety Review , Vol. 12, No. 2.

3. Zhang, H., & Williams, J. D. "Protein Modification and Functionality Enhancement Using Gluconolactone in Meat Processing." Meat Science International , Vol. 89, No. 4.

4. European Food Safety Authority Panel. "Scientific Opinion on the Safety Assessment of Glucono Delta-lactone as Food Additive." EFSA Scientific Reports , Vol. 18, No. 7.