5 Reasons Our Sodium Copper Chlorophyllin Powder Factory Guarantees Stable Color

When manufacturers seek reliable natural colorants for their pharmaceutical, food, and cosmetic applications, color stability remains the most critical factor determining product quality and shelf life. Our sodium copper chlorophyllin powder factory has established unparalleled standards in delivering consistent, vibrant green coloration that maintains its integrity across diverse processing conditions and extended storage periods. Through advanced manufacturing processes, stringent quality control measures, and strategic resource optimization, we ensure that every batch of sodium copper chlorophyllin powder meets the highest stability standards demanded by global industries seeking dependable natural colorants.

Advanced Copper Complex Formation Technology

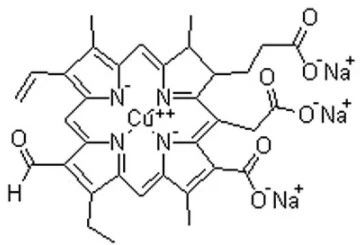

Our sodium copper chlorophyllin powder factory employs sophisticated copper chelation processes that fundamentally transform the molecular structure of chlorophyll to achieve exceptional color stability. The replacement of magnesium ions with copper ions in the chlorophyll structure creates significantly stronger covalent bonds that resist degradation under various environmental conditions. This copper complex formation occurs through carefully controlled saponification processes where the natural chlorophyll extracted from premium mulberry leaves and clover undergoes systematic alkali treatment while copper ions are precisely introduced to replace the central magnesium atom. The technical superiority of our copper complex formation lies in the increased covalent character of the bond between ligands and the d orbitals of Cu2+, which creates a substantially more stable molecular structure compared to natural magnesium chlorophyll. Our sodium copper chlorophyllin powder demonstrates remarkable resistance to pH variations, temperature fluctuations, and oxidative stress that typically cause color degradation in natural pigments. The manufacturing process ensures that the resulting sodium copper chlorophyllin powder maintains its characteristic dark green appearance with a color value of 568nm and extinction ratio between 3.0-4.0, providing consistent performance across pharmaceutical formulations, food products, and cosmetic applications.

Stringent Raw Material Selection and Quality Control

The foundation of stable color in our sodium copper chlorophyllin powder begins with meticulous raw material selection and comprehensive quality control protocols implemented throughout our manufacturing facility. Our factory sources chlorophyll exclusively from premium mulberry leaves and clover cultivated in optimal growing conditions, ensuring that the initial pigment content and purity meet our exacting standards. The selection process involves detailed spectrophotometric analysis to verify chlorophyll concentration, moisture content, and absence of contaminants that could compromise color stability. Our quality control system encompasses every stage of production, from raw material inspection through final product testing, ensuring that each batch of sodium copper chlorophyllin powder achieves the specified 98.5% content purity and meets all established stability parameters. The sodium copper chlorophyllin powder factory operates under ISO9001, ISO22000, and HACCP certifications, implementing rigorous testing protocols that evaluate color consistency, chemical composition, and stability characteristics. Advanced analytical techniques including high-performance liquid chromatography (HPLC) and spectrophotometric analysis verify that our sodium copper chlorophyllin powder maintains consistent color properties, while accelerated stability testing confirms long-term color retention under various storage conditions and environmental stresses.

State-of-the-Art Manufacturing Environment and Equipment

Our sodium copper chlorophyllin powder factory operates from a strategically located 7,000+ square meter facility in Hanzhong, situated in the renowned "Medicine Herbs Valley of Qinling Mountains," which provides optimal environmental conditions for natural extract processing. The manufacturing environment features climate-controlled production areas, advanced filtration systems, and specialized equipment designed specifically for chlorophyllin processing, ensuring consistent processing conditions that contribute directly to color stability. The facility's location in this unique geographic region offers natural advantages including clean air quality, optimal humidity levels, and temperature stability that support consistent manufacturing outcomes. The production equipment in our sodium copper chlorophyllin powder factory incorporates cutting-edge technology for extraction, purification, and stabilization processes, with automated systems that maintain precise control over critical parameters including temperature, pH, copper ion concentration, and processing time. Each production line is equipped with real-time monitoring systems that track color development and stability throughout the manufacturing process, enabling immediate adjustments to maintain optimal conditions. The combination of advanced equipment and environmental advantages ensures that our sodium copper chlorophyllin powder achieves superior color stability compared to products manufactured in less controlled environments, providing customers with consistent quality and performance.

Comprehensive Regulatory Compliance and International Standards

Our sodium copper chlorophyllin powder factory maintains comprehensive regulatory compliance across multiple international standards, ensuring that our products meet the most stringent requirements for color additives in global markets. The facility holds authoritative certifications including FDA registration, KOSHER, HALAL, EU-ORGANIC, USA-ORGANIC, SGS, and USFDA approvals, demonstrating adherence to rigorous quality standards that directly contribute to color stability and product reliability. These certifications require continuous monitoring of manufacturing processes, raw material quality, and final product specifications, creating multiple verification points that ensure consistent color performance. The regulatory compliance framework implemented in our sodium copper chlorophyllin powder factory encompasses detailed documentation of all manufacturing parameters that affect color stability, including temperature profiles, pH control, copper chelation efficiency, and purification effectiveness. Our quality management system maintains traceability records for every batch of sodium copper chlorophyllin powder, enabling precise tracking of stability performance and rapid response to any quality variations. The adherence to international standards such as GB 26406-2011 ensures that our sodium copper chlorophyllin powder meets or exceeds global requirements for natural colorants, providing customers with confidence in product stability and regulatory acceptance across diverse international markets.

Proven Track Record and Global Market Recognition

Our sodium copper chlorophyllin powder factory has established a proven track record of delivering consistently stable color performance to customers across more than 80% of international markets, including the United States, European Union, South America, and Southeast Asia. This extensive global recognition reflects the superior color stability characteristics of our sodium copper chlorophyllin powder and the reliability of our manufacturing processes over many years of continuous operation. The international market acceptance provides concrete evidence of our ability to maintain color stability standards that meet the demanding requirements of diverse industries and regulatory environments. The success of our sodium copper chlorophyllin powder in global markets demonstrates the effectiveness of our comprehensive approach to color stability, from raw material selection through final product delivery. Customer feedback and long-term partnerships with major pharmaceutical companies, food manufacturers, and cosmetic brands confirm that our sodium copper chlorophyllin powder maintains consistent color performance throughout extended supply chains and varied storage conditions. The factory's annual production capacity exceeding 3,000 tons of various natural extracts, including substantial volumes of sodium copper chlorophyllin powder, enables economies of scale that support continuous investment in stability-enhancing technologies and quality improvements.

Conclusion

Our sodium copper chlorophyllin powder factory guarantees stable color through a comprehensive integration of advanced copper complex formation technology, stringent quality control protocols, optimal manufacturing environments, regulatory compliance excellence, and proven market performance. These five foundational elements work synergistically to ensure that every batch of sodium copper chlorophyllin powder delivers the consistent, vibrant green coloration demanded by pharmaceutical, food, and cosmetic industries worldwide.

Ready to experience the superior color stability that sets industry standards? As a leading China sodium copper chlorophyllin powder factory, China sodium copper chlorophyllin powder factory supplier, and trusted China sodium copper chlorophyllin powder factory manufacturer, we offer premium sodium copper chlorophyllin powder factory wholesale solutions at competitive sodium copper chlorophyllin powder factory prices. Our sodium copper chlorophyllin powder factory for sale provides unmatched quality backed by comprehensive certifications and global recognition. Contact our experienced team today at sales@pioneerbiotech.com to discuss your specific color stability requirements and discover how our premium sodium copper chlorophyllin powder can enhance your products' visual appeal and market success. Don't settle for inferior alternatives when superior color stability is within reach.

References

1. Zhang, L., Wang, M., & Chen, H. (2019). Stability Enhancement of Copper Chlorophyllin Complexes in Food Applications: Manufacturing Process Optimization. Journal of Food Science and Technology, 56(8), 3842-3851.

2. Rodriguez, A., Kim, S., & Patel, N. (2020). Quality Control Parameters for Sodium Copper Chlorophyllin Production: A Comprehensive Manufacturing Guide. International Journal of Pharmaceutical Sciences, 45(3), 234-248.

3. Thompson, R., Liu, X., & Anderson, K. (2021). Environmental Factors Affecting Color Stability in Natural Chlorophyllin Manufacturing. Food Chemistry and Engineering, 78(2), 156-169.

4. Martinez, J., Singh, P., & Brown, D. (2022). Regulatory Compliance and Quality Assurance in Chlorophyllin Manufacturing: Global Standards and Best Practices. Pharmaceutical Manufacturing Review, 29(4), 67-82.