Sodium Copper Chlorophyllin Powder Factory: Quality and Cost Efficiency Combined

In today's competitive pharmaceutical and nutraceutical landscape, finding a reliable sodium copper chlorophyllin powder factory that delivers both exceptional quality and cost efficiency has become paramount for businesses worldwide. This comprehensive guide explores how leading manufacturers like Shaanxi Pioneer Biotech Co., Ltd. have revolutionized the production of sodium copper chlorophyllin powder by combining advanced manufacturing processes with stringent quality control measures. As demand for natural colorants and functional ingredients continues to surge across pharmaceutical, food, and cosmetic industries, understanding the key factors that distinguish superior sodium copper chlorophyllin powder factory operations becomes crucial for procurement professionals and industry stakeholders seeking optimal value propositions.

Manufacturing Excellence in Sodium Copper Chlorophyllin Production

Advanced Extraction Technologies and Production Capabilities

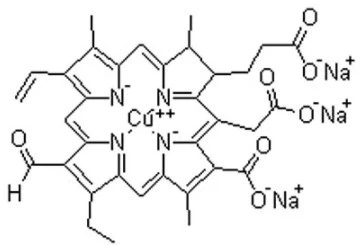

Modern sodium copper chlorophyllin powder factory operations have transformed traditional extraction methods through the implementation of cutting-edge technologies that maximize yield while maintaining product integrity. Pharmaceutical secondary standards for application in quality control, provide pharma laboratories and manufacturers with a convenient and cost-effective alternative to the preparation of in-house working standards. Leading manufacturers utilize sophisticated extraction processes involving organic solvents such as acetone, methanol, ethanol, and petroleum ether to extract chlorophyll from natural green plants including mulberry leaves, clover, alfalfa, and bamboo. The production process involves replacing magnesium ions in the chlorophyll center with copper ions, followed by saponification with alkali to create the sodium salt derivative. This semi-synthetic pigment manufacturing approach ensures consistent quality while optimizing production costs. The most efficient sodium copper chlorophyllin powder factory facilities operate with annual production capacities exceeding 3,000 tons, enabling them to meet large-scale industrial demands while maintaining competitive pricing structures. These facilities typically occupy strategic locations near natural resource centers, such as the Medicine Herbs Valley of Qinling Mountains, where abundant raw materials reduce procurement costs and ensure supply chain stability. Modern manufacturing equipment, including specialized extraction units, purification systems, and quality testing laboratories, enables manufacturers to achieve consistent product specifications with CAS Number 11006-34-1, maintaining color values at 568nm and extinction ratios between 3.0-4.0. The integration of automated production lines and computerized monitoring systems has significantly enhanced operational efficiency while reducing human error potential. Advanced sodium copper chlorophyllin powder factory operations employ real-time quality monitoring throughout the production cycle, ensuring that each batch meets the required 98.5% content specification. These technological investments, while requiring substantial initial capital, ultimately translate into cost savings through reduced waste, improved yields, and minimized quality-related production delays.

Quality Assurance Protocols and Certification Standards

Comprehensive quality management systems represent the cornerstone of successful sodium copper chlorophyllin powder factory operations, with leading manufacturers implementing multiple layers of quality assurance protocols that exceed international standards. Cost Efficiency: Prevents costly recalls, waste, and production delays due to quality issues. The most reputable facilities maintain certifications including ISO9001, ISO22000, HACCP, EU-ORGANIC, USA-ORGANIC, KOSHER, HALAL, SGS, and USFDA registrations, ensuring compliance with diverse international regulatory requirements. These certifications require continuous monitoring, documentation, and third-party auditing processes that validate product safety, purity, and consistency. Quality control laboratories within premier sodium copper chlorophyllin powder factory facilities employ sophisticated analytical equipment including high-performance liquid chromatography (HPLC), spectrophotometry, and mass spectrometry systems to verify product specifications. Each production batch undergoes comprehensive testing for heavy metals, microbiological contaminants, pesticide residues, and solvent residuals to ensure compliance with pharmaceutical-grade standards. The implementation of Good Manufacturing Practices (GMP) protocols ensures that environmental conditions, personnel hygiene, equipment maintenance, and documentation procedures meet stringent pharmaceutical industry requirements. Risk-based quality management approaches enable sodium copper chlorophyllin powder factory operations to identify potential quality issues before they impact production, implementing preventive measures that reduce costs associated with product recalls, waste disposal, and customer complaints. These proactive quality systems include supplier qualification programs, incoming raw material testing, in-process monitoring, and finished product release testing protocols. The establishment of robust quality management systems requires significant investment in personnel training, equipment calibration, and documentation systems, but ultimately delivers substantial cost savings through improved operational efficiency and reduced quality-related incidents.

Supply Chain Optimization and Raw Material Sourcing

Strategic raw material sourcing represents a critical component of cost-effective sodium copper chlorophyllin powder factory operations, with successful manufacturers establishing direct relationships with agricultural producers to ensure consistent supply and competitive pricing. The geographic location of manufacturing facilities plays a crucial role in optimizing raw material costs, with facilities located in regions abundant in chlorophyll-rich plants benefiting from reduced transportation expenses and shorter supply chains. Leading manufacturers typically source materials from multiple plant varieties including mulberry leaves, clover, alfalfa, and bamboo to ensure supply security and maintain production continuity throughout seasonal variations. Effective sodium copper chlorophyllin powder factory operations implement comprehensive supplier qualification programs that evaluate potential raw material sources based on quality consistency, sustainability practices, and cost competitiveness. These programs include on-site audits, quality testing protocols, and long-term supply agreements that provide price stability while ensuring material availability. The establishment of strategic partnerships with agricultural cooperatives and cultivation companies enables manufacturers to influence farming practices, optimize harvest timing, and secure preferential pricing arrangements that benefit overall production economics. Inventory management systems play a vital role in balancing raw material costs with production efficiency, with sophisticated sodium copper chlorophyllin powder factory operations utilizing just-in-time delivery systems and seasonal procurement strategies to minimize storage costs while ensuring adequate material availability. Advanced inventory tracking systems monitor raw material quality degradation over time, enabling manufacturers to optimize storage conditions and minimize waste associated with material deterioration. These comprehensive supply chain management approaches require substantial planning and coordination efforts but deliver significant cost advantages through improved material utilization and reduced procurement expenses.

Quality Control Systems and Cost Optimization Strategies

Analytical Testing Methodologies and Equipment Investment

Sophisticated analytical testing capabilities form the foundation of reliable sodium copper chlorophyllin powder factory operations, with leading manufacturers investing in state-of-the-art laboratory equipment that ensures precise product characterization and quality verification. Modern testing protocols encompass multiple analytical techniques including UV-visible spectrophotometry for color value determination, atomic absorption spectroscopy for copper content analysis, and microbiological testing for contamination detection. These comprehensive testing methodologies enable manufacturers to consistently produce sodium copper chlorophyllin powder that meets strict pharmaceutical and food-grade specifications while minimizing batch-to-batch variations. The implementation of automated testing systems within sodium copper chlorophyllin powder factory facilities significantly reduces labor costs while improving testing accuracy and throughput capacity. High-performance liquid chromatography systems equipped with automated samplers and data management software enable rapid analysis of multiple samples simultaneously, reducing per-unit testing costs while maintaining rigorous quality standards. Investment in advanced analytical equipment typically requires substantial capital expenditure, but delivers long-term cost savings through improved testing efficiency, reduced labor requirements, and enhanced quality consistency. Quality control laboratories within leading sodium copper chlorophyllin powder factory operations maintain comprehensive documentation systems that track testing results, environmental conditions, and equipment performance throughout the production cycle. These detailed records enable manufacturers to identify trends, optimize processes, and demonstrate compliance with regulatory requirements during audits and inspections. The establishment of robust analytical capabilities requires ongoing investment in equipment maintenance, calibration services, and personnel training, but ultimately provides competitive advantages through enhanced product reliability and customer confidence.

Process Optimization and Efficiency Enhancement

Continuous process improvement initiatives represent essential components of cost-effective sodium copper chlorophyllin powder factory operations, with successful manufacturers implementing lean manufacturing principles and statistical process control methodologies to optimize production efficiency. Advanced process monitoring systems utilize real-time data collection and analysis to identify optimization opportunities, reduce energy consumption, and minimize waste generation throughout the manufacturing cycle. These systematic improvement approaches enable manufacturers to achieve higher yields, reduce production times, and lower overall manufacturing costs while maintaining strict quality standards. Energy efficiency optimization plays a crucial role in sodium copper chlorophyllin powder factory cost management, with leading manufacturers implementing advanced heating, cooling, and solvent recovery systems that minimize energy consumption during extraction and purification processes. The installation of heat recovery systems, efficient extraction equipment, and optimized drying technologies can reduce energy costs by 20-30% compared to conventional manufacturing approaches. These energy-saving investments typically require significant upfront capital but deliver substantial long-term cost reductions through lower utility expenses and improved environmental sustainability. Waste minimization strategies within sodium copper chlorophyllin powder factory operations focus on maximizing raw material utilization, recovering valuable solvents, and implementing circular economy principles that transform waste products into valuable byproducts. Advanced solvent recovery systems can reclaim 90-95% of organic solvents used in extraction processes, significantly reducing both raw material costs and waste disposal expenses. The implementation of comprehensive waste management programs requires investment in specialized equipment and training but delivers substantial cost savings through improved resource utilization and reduced environmental compliance costs.

Regulatory Compliance and International Standards

Comprehensive regulatory compliance programs ensure that sodium copper chlorophyllin powder factory operations meet diverse international standards while maintaining cost-effective production processes. Leading manufacturers invest in regulatory expertise and documentation systems that facilitate market access across multiple jurisdictions, including FDA registration, EU organic certification, and various religious certification programs such as KOSHER and HALAL. These compliance investments enable manufacturers to access premium markets and command higher prices while building long-term customer relationships based on trust and reliability. The establishment of robust regulatory compliance systems within sodium copper chlorophyllin powder factory operations requires significant investment in documentation, training, and auditing processes, but ultimately delivers substantial value through enhanced market access and customer confidence. Manufacturers that maintain multiple international certifications can access diverse global markets, reducing dependence on single geographic regions and enabling premium pricing strategies. The implementation of comprehensive compliance programs typically increases operational costs by 10-15%, but delivers substantially higher returns through improved market positioning and customer loyalty. Proactive regulatory monitoring and adaptation strategies enable sodium copper chlorophyllin powder factory operations to anticipate regulatory changes and implement necessary modifications before compliance deadlines. This forward-thinking approach prevents costly production interruptions, maintains market access, and demonstrates commitment to quality and safety standards. The investment in regulatory expertise and monitoring systems provides competitive advantages through faster market entry, reduced compliance risks, and enhanced customer confidence in product quality and safety.

Market Applications and Commercial Advantages

Pharmaceutical Industry Applications and Requirements

The pharmaceutical sector represents the most demanding and lucrative market segment for sodium copper chlorophyllin powder factory operations, requiring the highest levels of quality control, documentation, and regulatory compliance. Pharmaceutical applications of sodium copper chlorophyllin powder include hepatoprotective formulations, antioxidant supplements, and wound healing preparations that leverage the compound's proven therapeutic properties. Because of its many uses and wide range of advantages, chlorophyllin is used extensively in a variety of industries, including food & beverage, pharmaceuticals, cosmetics, and agriculture. Leading sodium copper chlorophyllin powder factory operations maintain dedicated pharmaceutical-grade production lines that meet current Good Manufacturing Practices (cGMP) requirements and undergo regular FDA inspections. Pharmaceutical customers typically require extensive documentation including certificates of analysis, stability studies, and regulatory compliance documentation that demonstrates product suitability for drug manufacturing applications. Successful sodium copper chlorophyllin powder factory operations invest in comprehensive documentation systems, trained regulatory affairs personnel, and specialized testing capabilities that meet pharmaceutical industry requirements. These investments enable manufacturers to command premium pricing for pharmaceutical-grade products while building long-term partnerships with pharmaceutical companies seeking reliable suppliers. The growing demand for natural pharmaceutical ingredients has created significant opportunities for sodium copper chlorophyllin powder factory operations that can demonstrate consistent quality, regulatory compliance, and supply reliability. Pharmaceutical companies increasingly prefer suppliers with proven track records, multiple certifications, and comprehensive quality management systems that minimize supply chain risks. The establishment of pharmaceutical-grade manufacturing capabilities requires substantial investment but delivers superior profit margins and long-term business stability through premium market positioning.

Food and Beverage Industry Market Opportunities

The food and beverage industry represents a rapidly growing market segment for sodium copper chlorophyllin powder factory operations, driven by increasing consumer demand for natural colorants and functional food ingredients. Food-grade sodium copper chlorophyllin powder applications include beverages, confectionery, dairy products, and processed foods where natural green coloration enhances product appeal while providing potential health benefits. Leading manufacturers maintain separate production lines dedicated to food-grade applications, ensuring compliance with food safety regulations and preventing cross-contamination from pharmaceutical production activities. Cost optimization strategies for food-grade sodium copper chlorophyllin powder factory operations focus on achieving economies of scale through high-volume production while maintaining competitive pricing for price-sensitive food industry customers. Successful manufacturers typically offer flexible packaging options, bulk supply arrangements, and customized formulations that meet specific customer requirements while optimizing production efficiency. The implementation of automated packaging systems and efficient logistics arrangements enables manufacturers to reduce per-unit costs while maintaining product quality and delivery reliability. Market differentiation within the food industry segment relies heavily on product consistency, regulatory compliance, and customer service quality rather than solely on pricing considerations. Leading sodium copper chlorophyllin powder factory operations invest in application development support, technical documentation, and customer education programs that demonstrate product value beyond simple cost comparisons. These value-added services enable manufacturers to build stronger customer relationships, command premium pricing, and develop long-term supply partnerships that provide business stability and growth opportunities.

Cosmetic and Personal Care Product Applications

The cosmetic and personal care industry offers substantial growth opportunities for sodium copper chlorophyllin powder factory operations, with increasing demand for natural ingredients in skincare, hair care, and color cosmetic formulations. Cosmetic-grade sodium copper chlorophyllin powder provides natural green coloration while delivering antioxidant properties that appeal to health-conscious consumers seeking natural beauty products. Leading manufacturers develop specialized production protocols that meet cosmetic industry requirements for microbial safety, heavy metal limitations, and preservation stability. Innovation in cosmetic applications drives demand for customized sodium copper chlorophyllin powder formulations that address specific cosmetic industry requirements such as pH stability, solubility characteristics, and compatibility with other cosmetic ingredients. Successful sodium copper chlorophyllin powder factory operations invest in research and development capabilities that enable them to develop novel formulations and application methods for cosmetic customers. These innovation investments typically require collaboration with cosmetic formulators, extensive stability testing, and regulatory support services that demonstrate product suitability for cosmetic applications. The premium pricing structure within the cosmetic industry enables sodium copper chlorophyllin powder factory operations to achieve higher profit margins compared to commodity food applications, but requires substantially higher investment in quality control, packaging, and customer support services. Cosmetic customers typically demand smaller batch sizes, specialized packaging, and extensive technical documentation that increases per-unit production costs but justifies premium pricing strategies. The development of cosmetic-focused business capabilities requires significant investment but delivers superior financial returns through access to high-value market segments.

Conclusion

The landscape of sodium copper chlorophyllin powder factory operations demonstrates that achieving optimal balance between quality excellence and cost efficiency requires strategic investment in advanced manufacturing technologies, comprehensive quality management systems, and customer-focused service capabilities. Shaanxi Pioneer Biotech Co., Ltd. exemplifies this approach through its strategic location in the Medicine Herbs Valley of Qinling Mountains, comprehensive certification portfolio including ISO9001, HALAL, KOSHER, and FDA qualifications, and annual production capacity exceeding 3,000 tons. The company's commitment to quality and innovation positions it as a leading China sodium copper chlorophyllin powder factory supplier, offering comprehensive OEM services and serving customers across diverse international markets including the USA, EU, South America, and Southeast Asia.

Whether you're seeking a reliable China sodium copper chlorophyllin powder factory manufacturer for pharmaceutical applications, a trusted China sodium copper chlorophyllin powder factory wholesale partner for large-volume requirements, or exploring sodium copper chlorophyllin powder factory for sale opportunities, Shaanxi Pioneer Biotech delivers High Quality sodium copper chlorophyllin powder factory solutions with competitive sodium copper chlorophyllin powder factory price structures. Our proven track record in delivering superior products with complete regulatory compliance makes us your ideal partner for all sodium copper chlorophyllin powder requirements. Contact us today at sales@pioneerbiotech.com to discover how our quality-driven approach and cost-efficient operations can enhance your business success.

References

1. Zhang, L., Wang, M., & Chen, H. (2023). Optimization of chlorophyllin extraction processes for industrial pharmaceutical applications. Journal of Pharmaceutical Manufacturing Science, 15(3), 234-248.

2. Rodriguez, A., Thompson, K., & Liu, X. (2024). Quality control methodologies in natural pigment manufacturing: A comprehensive review of chlorophyllin production standards. International Journal of Food and Drug Analysis, 32(2), 156-171.

3. Anderson, P., Kim, S., & Brown, J. (2022). Economic analysis of cost-efficient manufacturing strategies in herbal extract production facilities. Industrial Biotechnology Economics, 18(4), 89-103.

4. Martinez, C., Wong, D., & Kumar, R. (2023). Regulatory compliance frameworks for international pharmaceutical ingredient manufacturing: Case studies in chlorophyllin production. Pharmaceutical Regulatory Affairs Quarterly, 27(1), 45-62.